New Release: HB07 Series Waterproof Branch Connector

August 19, 2025

JAE has released the HB07 Series waterproof branch connectors designed for electrical distribution wire harnesses. The connectors are ideally suited for use in construction and agricultural machinery, commercial vehicles, and various other heavy-duty construction work-related vehicles. These connectors are customizable to provide a wide range of circuit configuration options.

Overview

In construction and agricultural machinery, commercial vehicles, and other types of heavy-duty construction vehicles, cables used to distribute power to components, such as sensors, lights, and lamps are often branched multiple times. Often times wire harnesses are manufactured by splicing wires together by using adhesive-lined heat shrink tubing. However, this manual process can result in inconsistencies, leading to increased contact resistance and poor ingress protection. Additionally, since the spliced sections must be bundled with the main trunk of the wire harness, causing the trunk to become thicker. This makes it more difficult to route wire harness through the vehicle body.

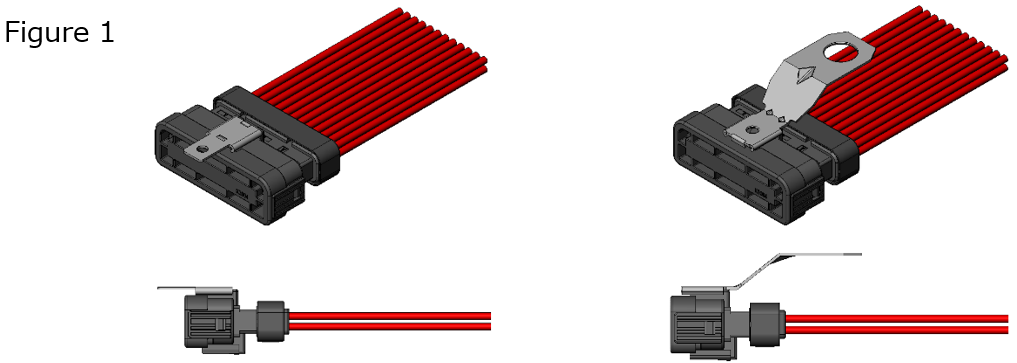

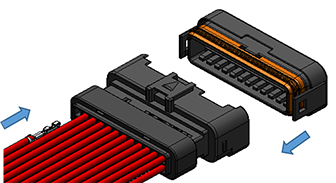

To address these issues, JAE has released the HB07 Series waterproof branch connectors, which can be used in a large variety of circuit configurations. By replacing the cable branching section with the HB07 Series connectors, it becomes possible to maintain consistent contact resistance and ensure reliable IP68 ingress protection. The product also allows for clips to be attached in either orientation (front or back) (see Figure 1), enabling secure mounting to the vehicle separately from the main wire harness. This helps reduce the thickness of the wire harness trunk and improves routing flexibility.

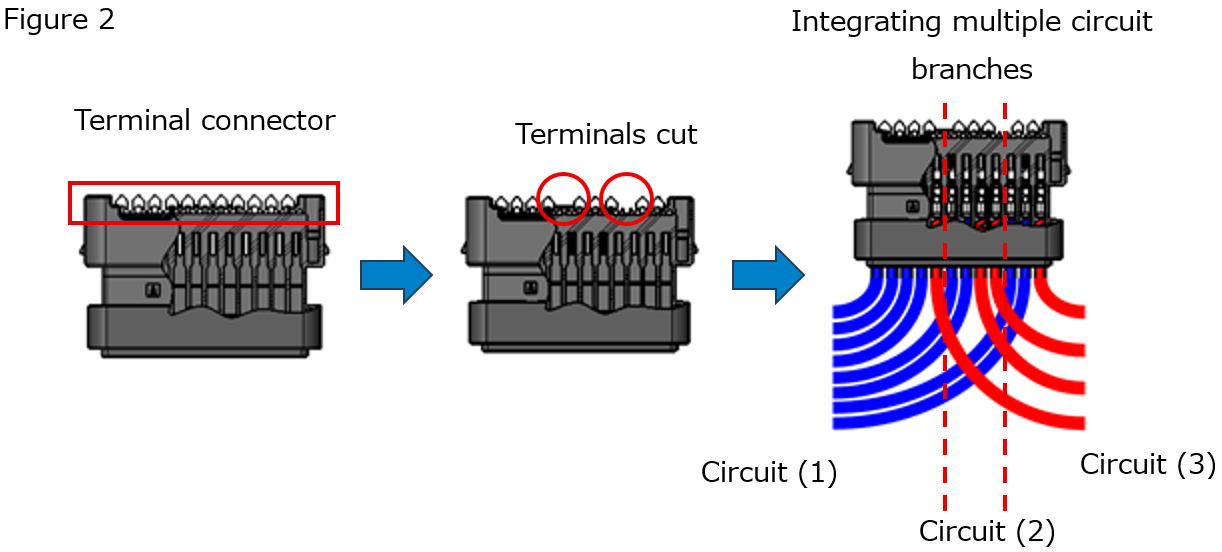

This product is available in a 12 position version (a single row of 12 position terminal connectors) and a 24 position version (two rows of 12 position terminals connectors). Depending on the desired circuit configuration, the shorting terminal can be cut at any point to modify which wires are shorted, allowing for custom branch harness creation. This enables the integration of harness branch sections with multiple circuit configurations, such as branching one power line into two, or two power lines into two, within a single connector, making it compatible with a wide range of circuit configurations. (see Figure 2)

Product Configuration

Features

- Customizable branch configurations

- IP68 ingress protection (submersion up to 2 meters)

- Number of positions: 12 or 24 (terminal connectors can be cut as needed)

- Compatible wire size: 0.5–1.25 mm2 (AWG #20–#16)

- Compatible with insulation outer diameter of φ1.5–2.9 mm

- Mechanical clip for secure connector mounting

Applicable Markets

- Power and signal branching connections for vehicle body harnesses in construction and agricultural machinery, special-purpose vehicles, and other types of heavy-duty construction vehicles

- Replacement of terminal blocks in various industrial equipment (provides waterproofing allowing for mounting outside the control box)

General specifications

| Number of Positions | 12, 24 | ||

|---|---|---|---|

| Rated Current | Wire size | Rated current | |

| 1.25 mm2 (AWG#16) | 13A | ||

| 0.85 mm2 (AWG#18) | 10A | ||

| 0.5 mm2 (AWG#20) | 7.5A | ||

| When performing branching from multiple wires to multiple wires, ensure that the total current at the merging point does not exceed 40A. (At Ambient Temperature of +25 deg.C) | |||

| Rated voltage | 250V DC | ||

| Applicable Wires | Part Number | Wire Size | Insulation Outer Diameter |

| HB07S03K3F1 | 1.25 mm2 (AWG#16) | φ2.0–2.9 mm | |

| HB07S04K4F1 | 0.5 mm2 (AWG#20) – 0.85 mm2 (AWG#18) | φ1.5–2.4 mm | |

| Ingress Protection | IP68 (submersion up to 2 meters) | ||

| Operating Temperature Range | -55 deg.C to +125 deg.C (Including temperature rise, Ingress protection at -40 deg.C max) | ||

Materials/Finishes

| Component | Materials/Finishes |

|---|---|

| Crimp contact | Copper alloy / Reflow tin plating |

| Insulator | PBT |

| Cover | PBT |

| Grommet | Silicone |

| Branch contact | Copper alloy / Tin plating over nickel |

| Cap | PBT |

| Sealing ring | Silicone |

HB07 Series (For more details)

Information and details given here are as of the date of publication. Please note that the details may be changed.