2021/10/07

-

Board to Board Connectors

MA01 Series Automotive Grade Floating Connectors

At JAE we are focusing on the development of ADAS (Advanced Driver Assistance Systems) and autonomous driving technologies by supplying high performance innovative connectors that aid in the efficiency and operation of today’s leading vehicle technology. To ensure the highest level of safety and performance, it’s essential to equip vehicles with high-performance on-board ECUs (Electronic Control Units) capable of processing large amounts of information at a given time. The use of multiple boards within these advanced ECU’s has resulted in increasing demand for higher quality and more reliable connector solutions to connect the multiple boards within each unit.

Our new MA01 Series of floating board-to-board connectors solve many of the issues found in today’s automotive ECU applications, like misalignment during assembly, design limitations, spacing constraints and more.

Features

Absorption of Positional Shifts during Robotic Assembly

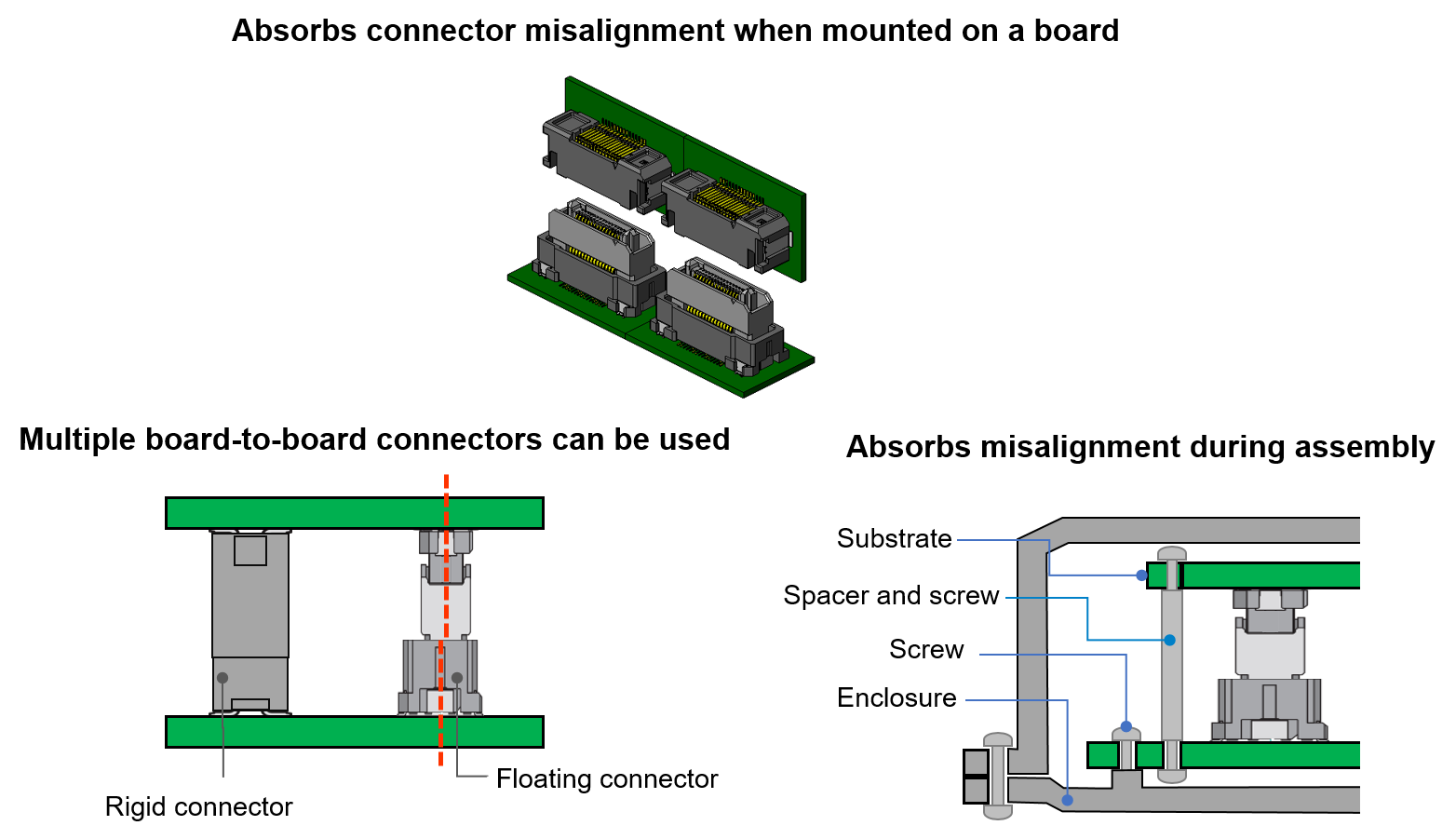

In the past, manufacturers had to accommodate for the misalignment of rigid connectors via robotic assembly using many manual techniques, ultimately wasting significant time and money. Today, both rigid and floating type connectors are available, allowing many manual assembly processes to be eliminated with floating contact technology. Floating type connectors feature floating contacts, which provides flexibility during mounting and works to absorb up to +/-0.5mm positional displacement caused when mounting on a board or assembling with a robot.

Additionally, floating connectors are also designed to absorb mounting errors and positional shifts even when multiple pairs of connectors are being used on a single board, allowing for increased flexibility of board layout and circuit design.

Conversely, with a rigid connector, without floating functionality, any misalignment in mounting could lead to the connector breaking during engagement. Even if engagement is possible, if the connector set experiences vibration or impact, or if heat is applied to the solder joint while stress is being applied, the solder may crack, causing conduction failure. With its floating structure, the MA01 Series connectors solve many problems like this caused by the use of rigid connectors in robot operated automated assembly.

Improved Efficiency of Assembly

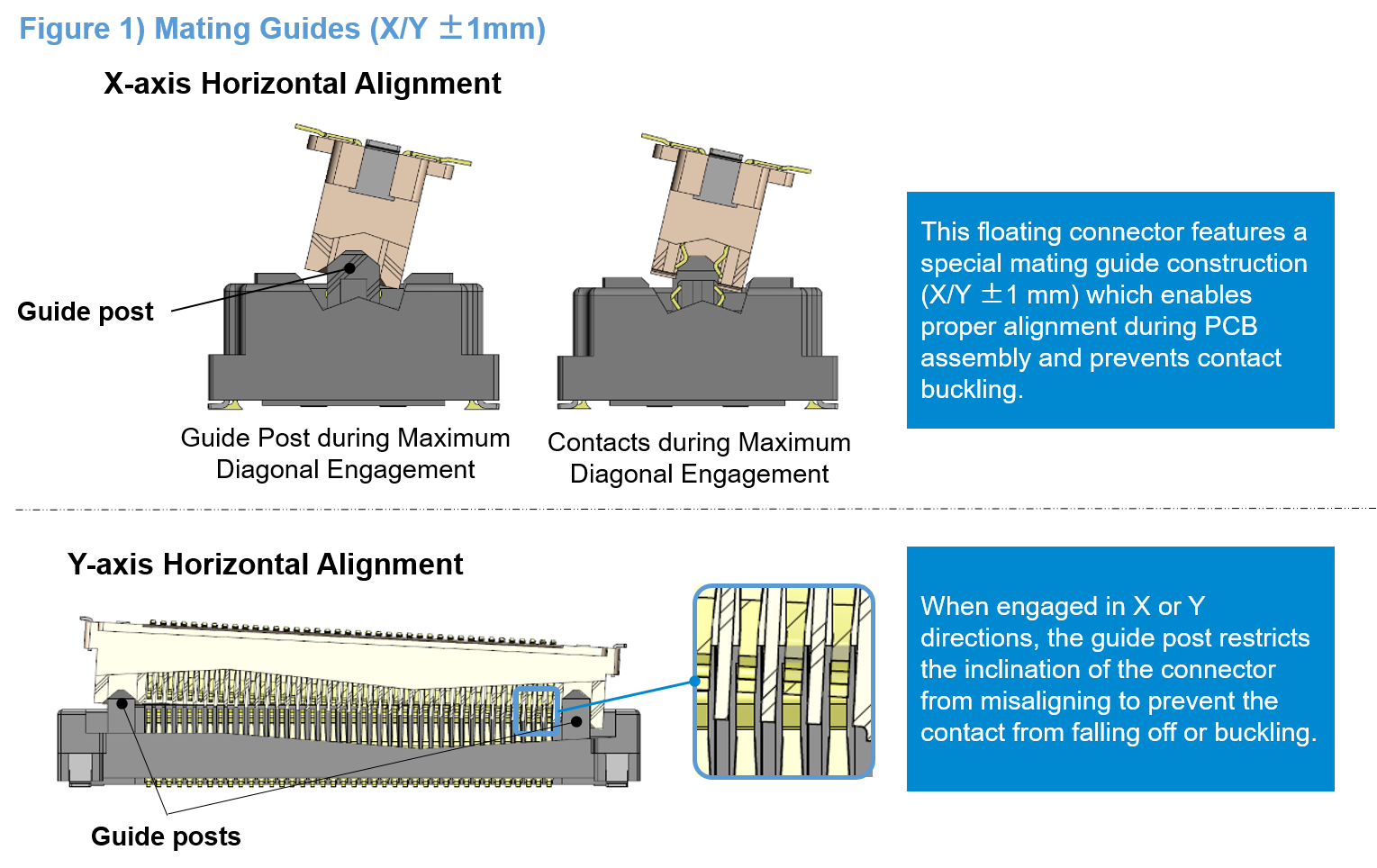

During the PCB assembly process placement precision is a must; however, many times board-to-board connectors need to blind mate during this process causing misalignments to occur with traditional rigid connectors. Considering this blind engagement and potential misalignment that can occur, connectors not designed to accommodate such conditions may induce contact buckling during board assembly work. Furthermore, if the assembly workmanship is inadequate and the contact buckles, not only can it not transmit signals, but the repair often takes a great deal of time.

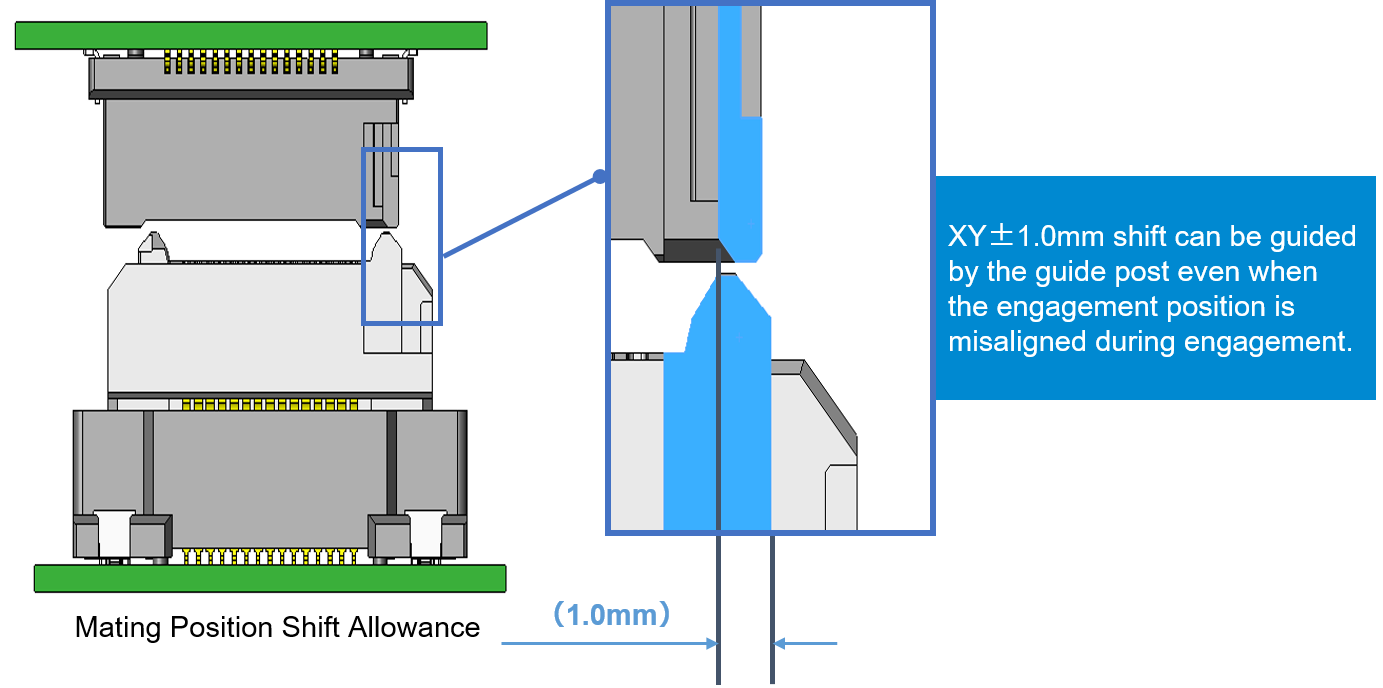

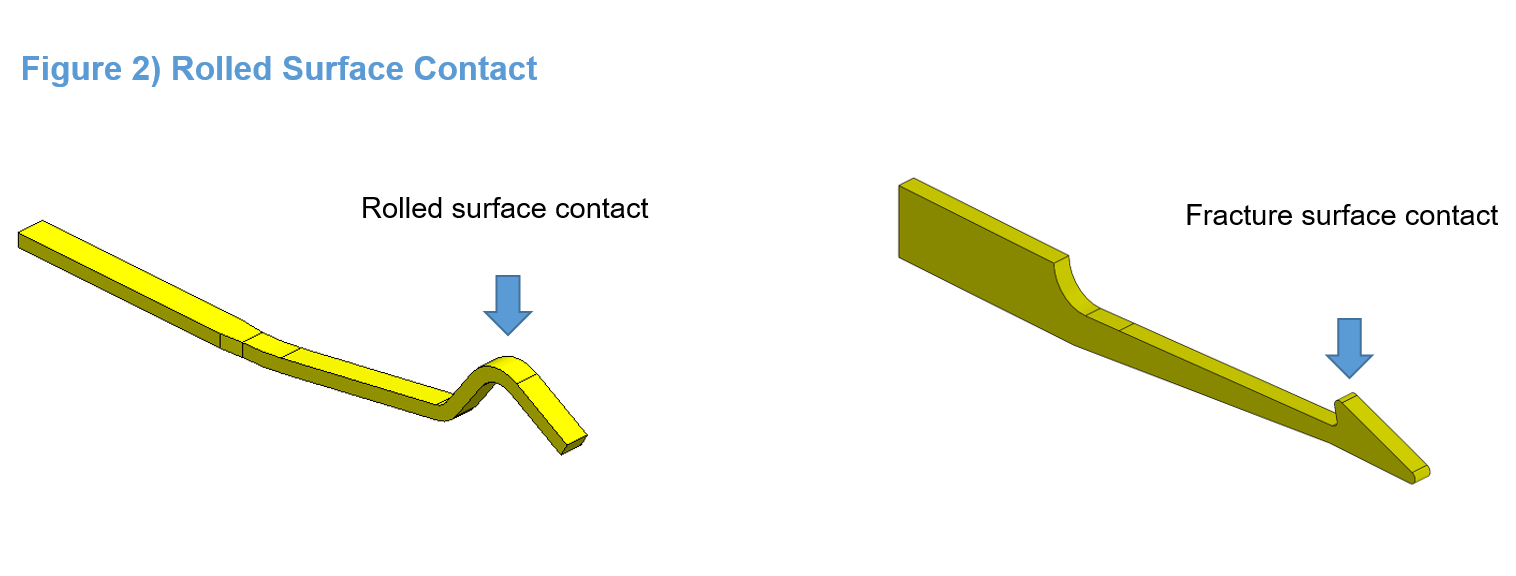

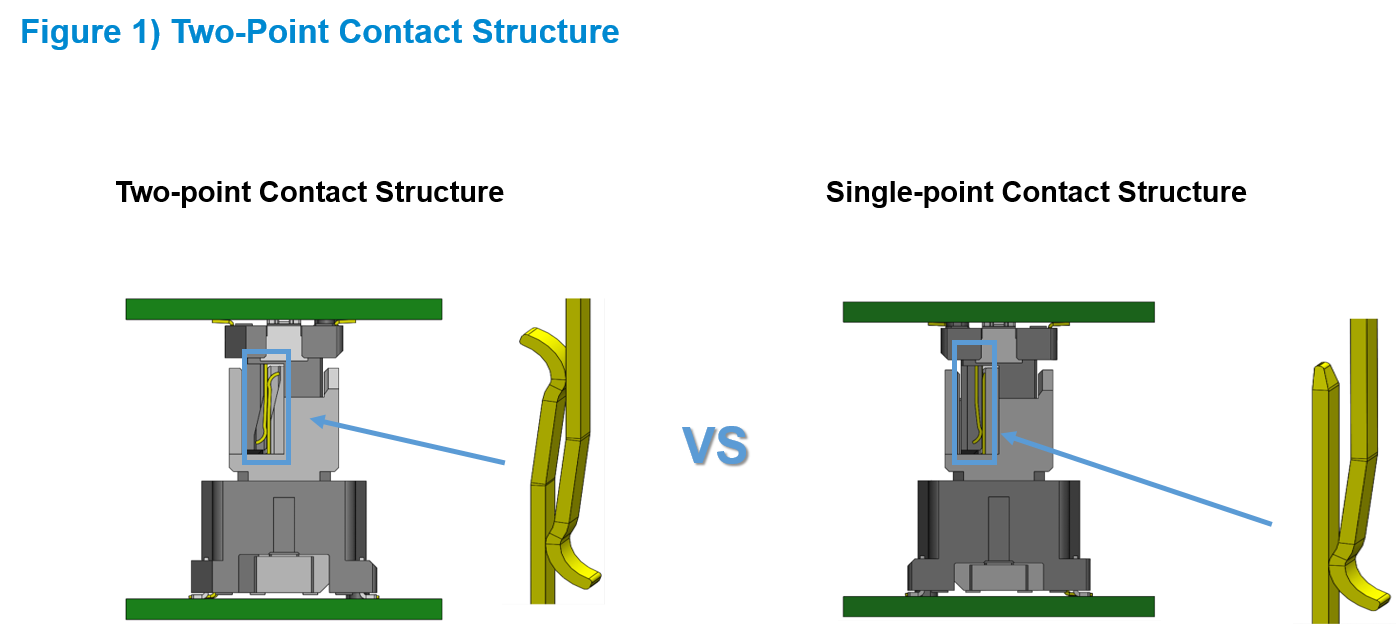

The MA01 series floating connector provides a guide post for diagonal engagement from the X and Y directions, limiting the inclination of the connector to shift to the side, and preventing the contact from falling off and buckling. The guide post also serves as an induction during engagement, and can be used for blind mating or automatic assembly by robots, allowing engagement of up to 1.0mm in either X and Y directions (see Figure 1). The contact point of the terminal is not a fractured but a rolled surface, which prevents wear of the plating and provides excellent mating operability, even with low insertion/extraction force and a large number of contacts (see Figure 2).

Higher Contact Reliability and Transmission Speeds

The products we use in our daily lives are changing dramatically with the evolution of technology over the past several decades. Automobiles among other high tech equipment continue to advance with the evolution of technology, equipped with high quality devices like on-board cameras and advanced driver assistance systems (ADAS), all while autonomous driving is soon to be a reality . It goes without saying that these changes require an increase in the amount of information processed by automobiles. For this reason, higher transmission speeds are an essential requirement for connectors used within automotive applications as well.

The MA01 Series floating connector provides a highly reliable two-point contact structure which supports 8Gbps+ (equivalent to 10GBASE-KR, PCIe Gen3), with higher contact reliability and faster transmission than conventional floating connectors.

Protection from Foreign Contaminants

High quality and reliability are essential in connectors used in automotive applications as electronic controls of vital equipment are rapidly becoming more sophisticated and where failure of connectors may lead to a serious accident. Today the main cause of failure among connectors used in automotive applications are the continuity disrupted by foreign contaminants between contacts within the connector.

In many cases foreign contaminants getting sandwiched between contacts will likely occur during board mounting or assembly of the connectors. With many connector solutions, it is very difficult to visually inspect for foreign contaminates, such as dust, gas, and flux, at the connector’s contact areas, since it is impossible to check the contact condition from the outside while the connectors are engaged. There are many cases where a single-point contact structure, as shown in Figure 1, is adopted for a general board-to-board connector, therefore contact failure is likely to occur if foreign contaminants get into the connector.

The MA01 Series, floating connector, has a two-point contact structure to prevent such problems. Even if foreign contaminants get in between one of the contact points the other contact point will remain unobstructed and strong contact reliability can be maintained.

Easy Mounting and Inspection

When mounting the SMT connector on a board it’s necessary to secure a "suction surface" on the top of the connector that the mounting vacuum nozzle can adhere to. Since vertical/straight connectors come with large openings on the top surface, it is difficult to secure a large enough suction surface. There are many cases in which a suction surface is provided using polyimide tape. If the tape is attached to form the suction surface, and the area where the tape is applied is small the adhesive force of the tape cannot withstand the vacuum-nozzle suction may cause mounting error.

With the MA01 Series, a “suction surface” is provided by the attached cap to prevent errors during the automatic pick and place process. The cap also doubles as a protective cover where it will shield the entire mating surface from flux, dust and other foreign contaminants infiltrating the connector during the mounting process. Additionally the horizontal connector is shaped to be easily inspected from the top (Figure 2), making visual inspection of termination simpler.

MA01 Specifications and Variations

Catalog Download: MA01 Series Floating Connectors

Download our comprehensive brochure to learn more about MA01series high speed floating board-to-board connector

Subject to change without notice. Errors and omission excepted.