Environmental Report 2017

Zero Emissions

The JAE Group makes effective use of resources by reducing general waste and consuming less paper, while promoting recycling and the sale of valuable resources through the exhaustive sorting of waste, such as scrap plastic and metal.Zero Emissions Activities

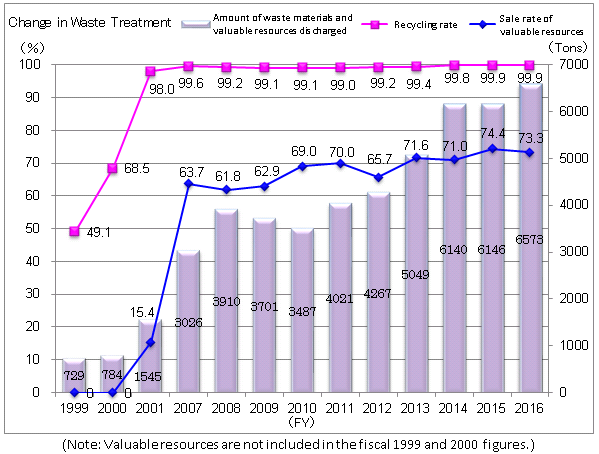

After launching its zero emissions efforts in fiscal 2000, JAE achieved a recycling rate of 99% in fiscal 2004. This level reached a high point of 99.8% in fiscal 2014. As a result, the goal was raised to over 99.5% in fiscal 2015 and to over 99.9% in fiscal 2016.Thanks to the JAE Group’s efforts to promote the sale of plastic and metal waste, the sales rate of all valuable resources has exceeded 60% since fiscal 2006. In addition to reducing costs for waste treatment, the sale of valuable waste contributes to resource saving and the reduction of CO2 over the life cycle of products. The Group aims to achieve even higher rates of sales.

Note: The JAE Group defines zero emissions as achieving a recycling rate of 99.5% or higher for waste defined by local ordinances, excluding waste that is disposed of by incineration and simple landfills.

Change in Waste Treatment

Efforts for Proper Disposal of Waste Materials

The JAE Group is implementing proper disposal of waste materials in accordance with Japan's Waste Disposal Law. The Group conducts compliance studies on subcontractors that handle all types of industrial waste, general waste, and valuable resources at the time of contract signing and thereafter by periodically checking their licenses and performing on-site inspections.To increase the transparency of its industrial waste disposal, in fiscal 2011, JAE began to electronically maintain industrial waste manifests. Now, across the entire Group, it has been able to achieve electronic manifest operations for 100% of participating suppliers. JAE continues to strive to properly process waste materials

Main Activities in Fiscal 2016

The main efforts made by sites to reduce wastes are shown below.Letters in parentheses, such as JAE, HAE, YAE and SAE, are abbreviations of the sites that carried out the activities.s

- Promotion of waste material recycling (JAE)

Given the progress in processing technology, and with a view to the environment (Scope 3) and other considerations, JAE reviewed the details of how it had been conducting processing for each waste product category, in an effort to qualitatively improve recycling and reduce processing costs. We are prioritizing new waste generated by the production of new items and waste discharged in large quantities due to volume production, and we are promoting value-added recycling by removing metal from composite waste materials and other means. - Promotion of waste plastic recycling (JAE)

JAE continues to tackle the issues of raising the qualitative recycling level and cutting processing costs by thoroughly separating waste according to the different types of waste plastic material, reviewing processing details and the selection of recycling vendors. - Promoting the recovery of valuable waste plastics (JAE, HAE, YAE)

The JAE Group is striving to improve the sales rate of waste plastics by thoroughly sorting them during recovery, promoting reuse within the company, liaising with recycling firms, and other measures. We turned one-way plastic pellets, which are used when materials are delivered from outside Japan, into valuable waste. - Promoting the recovery of valuable waste metals (HAE, YAE, SAE)

Exhaustive efforts to sort and recover waste metals contribute to efficient resource utilization and are helping to improve the rate of valuable waste that can be sold. - Recycling cleaning fluids (YAE)

To promote the recycling of cleaning fluids, the company completely separated the recovery of waste oil and waste fluids and redefined them as saleable substances, rather than waste, reducing waste to zero. - Reducing waste by lowering process defects (HAE, YAE, SAE)

The company is cutting waste by reducing the rate of defects, setting targets for the process defect rate and so on. The defect rate was reduced in line with the target by improving quality and workability through measures such as upgrading tools and procedures, reinforcing component target value management, and enhancing the skills of workers. This resulted in commensurate waste reductions.

The company will continue its efforts toward eradicating defects and promoting manufacturing that is environmentally friendly.