Development of a new technology wearzerO™, which is able to reduce wear on the silver plating of connectors

April 22, 2022

JAE has developed wearzerO ™, a new technology that will greatly reduce the wear of silver plating in electrical connections―a long-standing issue in development of connectors for electric vehicles (EVs). This technology has great potential to create a contact which has both high conductivity and excellent durability, and contributes to saving of plating material, energy conservation of the plating process as well as longevity of the products. In the future, we will step up our efforts to expand wearzerO ™ applicability to EV-specific charging plugs and in-vehicle power line connectors, in order to accelerate commercialization.

■Background

Since activities have recently been developed worldwide to reduce greenhouse gas emissions and help solve climate change issues, interest in mobility for the next generation is increasing, mainly in EVs.

For EV charging connectors, we are faced with new requirements for higher performance than previously seen in conventional automotive connectors, such as high voltage and high current. On the other hand, environmental considerations and sustainability are essential, including the manufacturing process.

In particular, silver plating with low electrical resistance is used to prevent loss at electrical contacts, since a large current is necessary in order to “reduce charging time,” for the wider use of EVs. Since the silver plating is soft, there is a problem since the silver plating of the contacts wears out due to repeated mating, etc., leading to deterioration of electrical and insertion/pullout characteristics.

To solve this problem, the industry has been developing new technologies for hardening silver plating and for a composite silver-plating which includes lubricating particles. However, hardening has a limit in wear resistance, and composite silver plating has a complicated manufacturing process and a large environmental load. These are also new issues for us to tackle.

■Characteristics of the technology

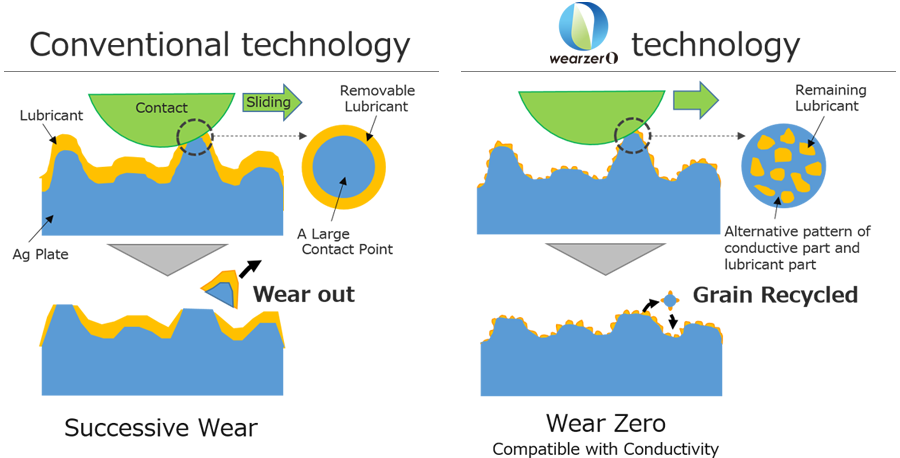

To solve these technological challenges, we have developed a technology wearzerO ™ that virtually zeroes the wear of silver plating. wearzerO ™ is a new technology which is designed to restrain adhesion between silver surfaces that cause wear of silver plating by forming a special interface structure on the sliding part of the silver plating (the part where the contact points come in touch with each other and cause friction). This special interface design allows the silver-plated surfaces to come into contact with each other to the extent that electrical conduction is not disturbed. On the other hand, disengagement is repeated in a manner to restrain wear progress, in which the contact is provided high conductivity and wear resistance.

In addition, since this technology can be applied to electrical connection terminals plated with only a few μm of standard soft silver, environmentally friendly connectors can be manufactured, featuring advantages such as saving of resources, saving energy in plating processes, and reducing waste due to improvement in the product life span.

Mechanism of wearzerO ™

In the future, we will apply this technology to manufacture of fast charging connectors for EVs and high current connectors for automotive power lines, and we will move toward commercialization.

The trademark "wearzerO ™" represents JAE's unique contact interface design technology that greatly reduces wear on metal plating at connector contacts. In this word "wearzerO ", symbolizing the image of JAE challenging innovative technology, we express our desire to contribute to the realization of a sustainable world.

Contact Us

Feedback

Japan Aviation Electronics Industry, Ltd.

Corporate Planning and Investor Relations Div.

21-1, Dogenzaka 1-chome, Shibuya-ku, Tokyo 150-0043, Japan

Tel : +81-3-3780-2711 Fax : +81-3-3780-2733

Information and details given here are as of the date of publication.

Please note that the details may be changed.