About Connectors

Connectors are electronic components that link the flow of electric power and data signals.Connectors are used in modern society everywhere you look. We would like to introduce you to the functions and features of connectors, and the technology and production processes that support them.

Key Technologies that Support Connectors

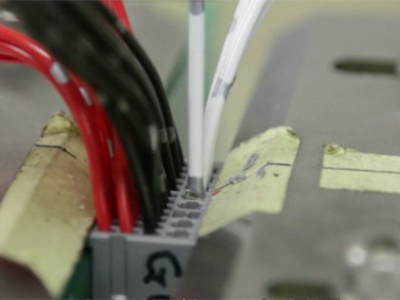

The role of connectors is to provide a stable link for electric power and signals in whatever environment the electronic devices are working. We will now look at several key technologies that improve the reliability of connectors.Contact Reliability Technology

In contact reliability technology, it is most important that the electric power and signalsare not interrupted | do not fluctuate | do not attenuate

In order to provide a stable electric connection, metal is formed or stamped to operate as a spring contact. Even if the connector and contacts are cycled many times, the spring contact must always return to its original position, and maintain the same contact force.

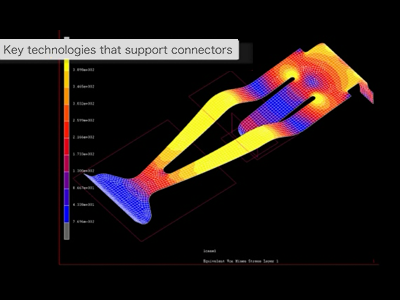

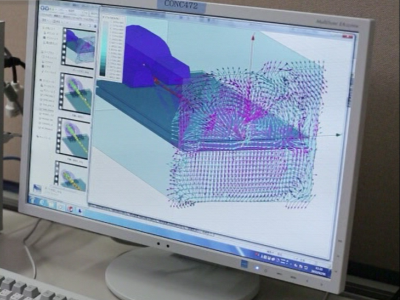

Simulation and Analysis Technology

A sophisticated contact design is required to successfully transmit a high frequency waveform through the contact without generating electromagnetic noise which can cause equipment to malfunction. For that purpose, simulation tools are employed from the design phase, to perform careful evaluation of the connector performance.

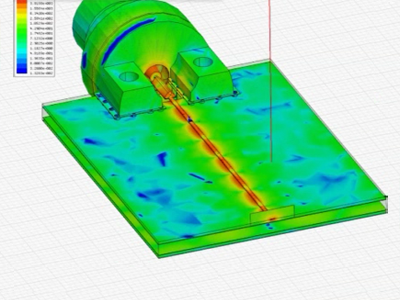

Environmental Resistance Technology

When a connector is used in a harsh environment such as an automobile, it is regularly exposed to high vibration and shock, as well as weather conditions such as extreme temperatures, humidity, rain and wind. Providing a stable connection with resistance to environments of exhaust gases and dust is also an important technology. JAE conducts various tests to verify connection and connector reliability.