2025/05/13

-

Board to Cable Connectors

High Voltage Connector “MY05 Series” for Battery Management System

Without a doubt, the dramatic changes happening now around the global automobile market is something that occurs once in a century. Various technological evolutions are progressing based on the megatrend Connected, Autonomous, Shared & Service, Electric (CASE).

Of particular importance is the shift to electrification. From the standpoint of decarbonization and carbon neutrality, there is no room for doubt that the shift to electrified vehicles continues to accelerate in the development of new vehicles. Electric vehicles (EVs) have actively been developed in various regions in the world, including Europe and China, which are leading the way. Furthermore, the same trend goes with countries in North America and in Japan, and their market continues to expand steadily. The EV development accelerates further. Thus, the number of market introductions of EVs will likely start to increase from 2025.

In the development of next-generation EVs, makers put emphasis on improving the performance and the driving distance on a single charge. Consequently, batteries constituting a key device are required to have higher capacity, which results in longer charge times. To compensate this, increasing the charging voltage is a significant factor. Therefore, EV manufacturers and battery-related companies are making every effort to develop the technologies closely related to next-generation EVs.

BCU Voltage Increases

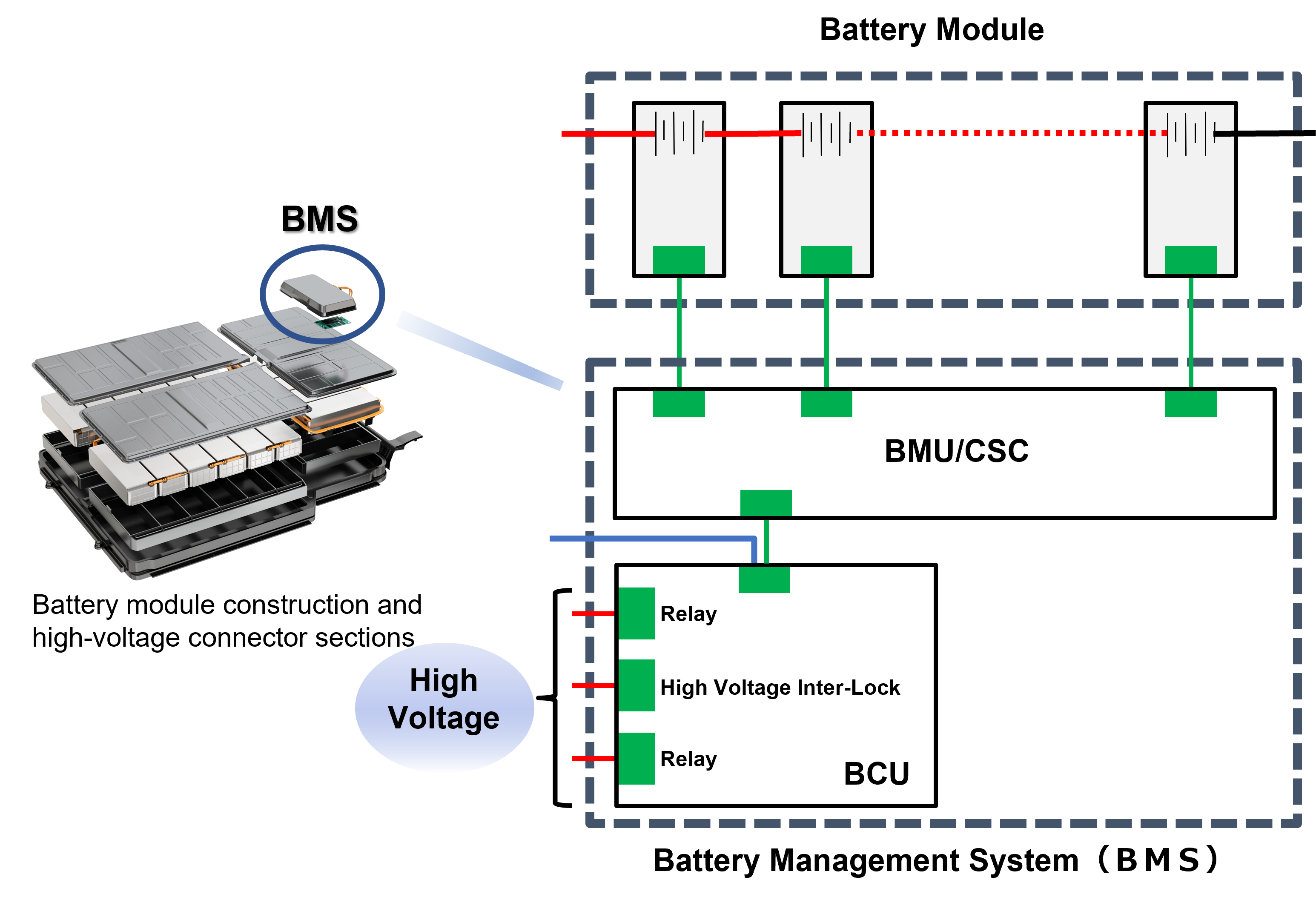

A battery pack installed in an EV consists of various units such as a battery module in which multiple battery cells are bundled together, a battery monitoring unit (BMU), and a battery control unit (BCU). Various connectors are used for joining these units together.Particularly, the BCU connector needs to be compatible with high voltages for monitoring of the voltage of a battery pack. Furthermore, the support of high voltages such as 800 V 1,000 V is required for next-generation EVs.Japan Aviation Electronics Industry (JAE) was quick to respond to these needs and developed the MY05 series of 1,000V high-voltage, low-current connectors for EV BMS.

Variations of Products Supporting High Voltages

The MY05 Series, which is currently under development for mass production, is a compact connector with a rated voltage of 1,000 V(DC). The operating temperature range is between minus 40 degrees and plus 125 degrees.

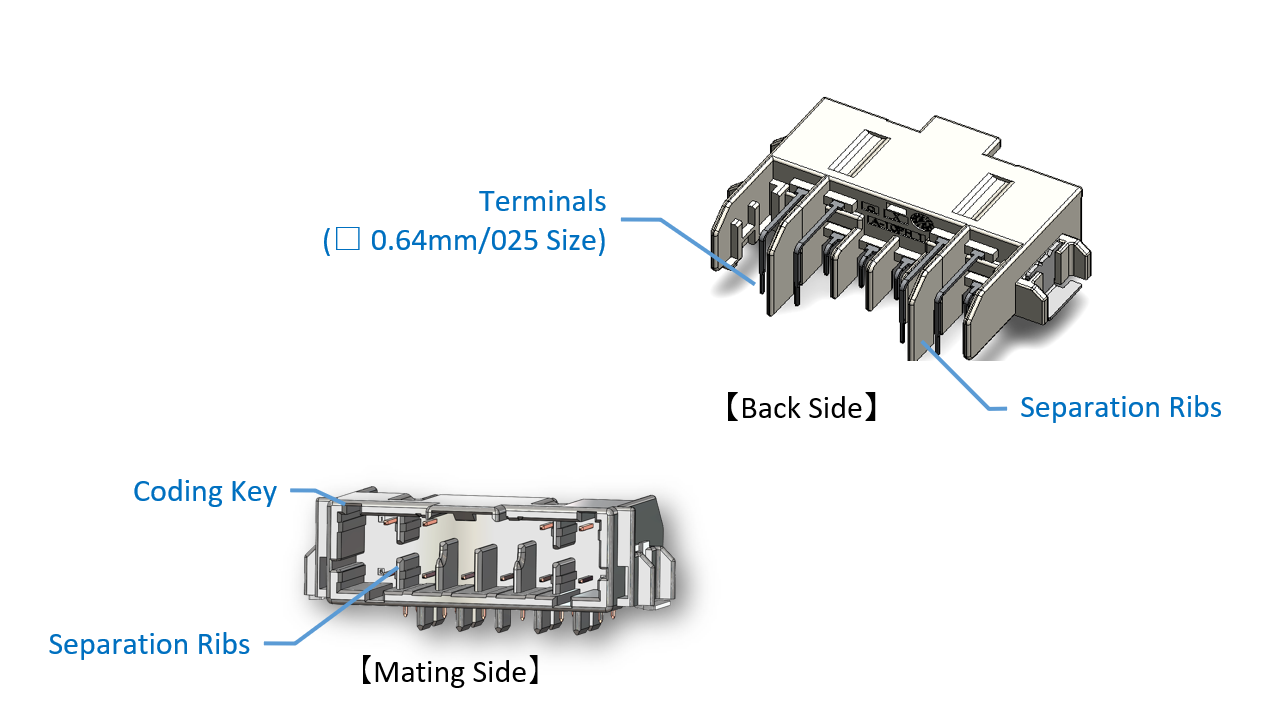

PCB Headers in both right-angle and straight orientations will become available.In addition, two types of sockets; with and without CPA will become available. The CPA type guarantees correct mating position by fixing the lock after mating.To add further product variation, MY05 connectors can support either JAE’s MX80 terminal or other terminals*, both widely used 0.63/0.64mm terminal systems, thus offering four variants within the planned lineup. With this variety, the tier-1s can select MY05 with confidence, knowing that the OEMs preferred terminal system will be supported.Terminal plating in both Silver and Tin plating types will be available.The number of contacts per connector planned will be 10, 14.

Addressing BCU Connector Challenges

When developing low voltage connector systems, Engineers have always considered factors such as contact resistance and dielectric insulation between terminals, but high voltage connectors call for additional, careful considerations. At high voltages, factors such as creepage and clearance distances come into play. Conditions such as operating voltage, the environment and the type of materials used means that terminal separation calculations are vital. The IEC specification provides a basis of these calculations and unless carefully followed, high voltages and short insulation distances can lead to short circuits and other problems.With the absence of suitable connector solutions in the market, connecting EV battery packs to BCU has been challenging and led to the use of far less than satisfactory solutions being adopted. For example, by using high-voltage connectors from industrial machinery or home appliances being used with pins removed. Alternatively, by using existing low-voltage connectors, but to meet the creepage and clearance distance requirements, some terminal cavities have remained empty. An extremely inefficient solution from the geometric size viewpoint. For high-voltage connectors, such as those for industrial machinery and home appliances, the maximum voltage remains limited and suited to 600V battery packs.For some time, there has been a market gap for automotive connectors that offer both full compliance with the IEC requirements and genuine suitability for harsher automotive environments & specifications. For this reason JAE developed MY05, a connectors series compatible of the 800V - 1,000V specifications necessary for the future EV market. The new design addressed the realization of high-voltage compatibility coupled with miniaturization.In the development of this series, JAE adopted a structure with separation ribs between the terminals for the purpose of reducing the size of the product while ensuring the insulation distance between the terminals. The result is a product that not only addresses miniaturization, but fully conforms to the creepage & clearances distance requirement defined within the IEC design standard.

Separation ribs secured creepage distances

Achieving the Highest Industry Specifications

The specifications of the MY05 series are as follows: The rated voltage is DC 1,000 V and the withstand voltage is DC 4,800 V. It is compatible with the extremely stringent OEM specifications such as LV215 and USCAR 37.In addition, the distance between terminals conforms to the IEC60664 standard. The dimensions are 50.5 mm wide × 15 mm high (10 position).

The product size may be slightly larger than that of competing products, but in terms of performance such as the withstand voltage and the distance between terminals, it complies better with IEC standards and meets the highest standards for preventing fires caused by high-voltage short circuits in connectors.

JAE has been offers a wide range of connectors for EV battery packs. In addition to high-voltage connectors for BMS, it has commercialized connectors for the cell module connection and the BMU connection.It can meet customer needs with the product lineup having low profile, lightweight, and wide range of pin counts.

MY05 Series Product Information

Products Supporting High Voltages

MY05 Series

Click here for product details of MY05 series.

Subject to change without notice. Errors and omission excepted.