Environmental Report 2014

Eco-friendly Products

Product-Related Efforts

Eco-friendly efforts starting from the design stage are underway in order to reduce environmental impacts at each stage from product manufacturing and use to disposal.

In product design, materials with low toxicity are being used and products are being made more energy efficient. And in mold design, other eco-friendly efforts are being pursued, including improving the utilization rate of mold materials and increasing the life of the molds themselves.

The eco-friendly efforts for each product are introduced below.

Examples of Eco-friendly Products

Connectors

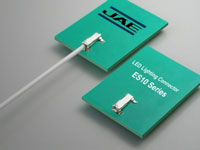

ES10 Series of Single Wire Insert Type Connector

(1) Conserving resources through product design

The ES10 Series offers a compact, low-profile design with no insulator. This contributes to a reduction of required resources, and, with a spring-type design that can be tucked in from both sides, contact reliability is enhanced. One-piece construction is also possible with strengthened extraction capabilities, which helps save on resources.

(2) Customer energy savings through product specifications

Connects simply by inserting the stripped wire into the connector, making work processes far fewer than compared to when the cable is soldered to the substrate. In addition, a guiding mechanism makes assembly easy, eliminating the need to worry about cable direction. Use of this guiding mechanism also makes it possible to save on labor.

(3) Customer energy savings by product delivery format

Available in embossed reel packaging for automated mounting. In addition, a built-in guiding mechanism means consistently automated product completion.

(4) Eco-friend specifications (RoHS directive-compliant products)

Lead-free solder is used for soldered contacts and no substances banned by the RoHS directive are used.

User Interface Solutions

LCD touch panels (UT3 series)

(1) Reduction in usage of environmentally hazardous substances

In addition to the use of lead-free solder alloy and the adoption of trivalent chromium surface processing and other measures for RoHS Directive compliance, the adoption of LED backlighting made

it possible to eliminate mercury.

(2) Lowering electricity consumption when power is not needed

Installation of an auto power save function lowers electricity consumption when not in use.