Environmental Report 2019

Eco-friendly Products

Product-Related Efforts

Eco-friendly efforts starting from the design stage are underway in order to reduce environmental impact at each stage, from product manufacturing and use to disposal. In product design, materials with low toxicity are being used, and products are being made more energy efficient. And in mold design, other eco-friendly efforts are being pursued, including improving the utilization rate of mold materials and increasing the life of the molds themselves. The eco-friendly efforts for each product are introduced below.Examples of Eco-friendly Products

Connectors

V2G connector KW03 series

(V2G:Vehicle to Grid)

(V2G:Vehicle to Grid)

(1) Expand use of renewable energy

The V2G system, to which this product applies, utilizes the massive storage capacity of electric vehicles in society as a whole, and can help absorb fluctuations of unstable renewable energy (solar and wind power generation, etc.) output, leading to expanded use of new energy sources with low environmental impact.

(2) Improvement of energy usage efficiency

Use of the V2G system, to which this product applies, enables the efficient use of energy by utilizing electric power that was charged when demand for electricity was low, during times of high demand.

(3) Resource-saving design

The body was designed to be smaller and lighter than conventional EV rapid-charge connectors, and the cable, which uses the most material, was made thinner, thereby reducing the amount of material needed. We also sought to standardize parts with the rapid-charge connector as much as possible, and reduced equipment production.

(4) Environmentally compatible specifications

Constituent materials are environmentally friendly in response to the RoHS Directive

User Interface Solutions

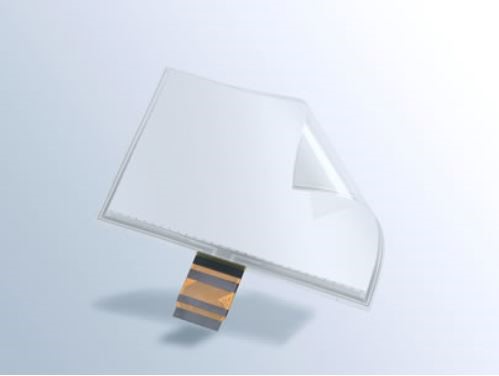

Automotive film sensor (TC23 series)

(1) Resource saving due to product structure

We changed the touch screen sensor from conventional glass to film in order to lighten unit weight and reduce the product’s weight compared to conventional products.

(2) Reduced usage of rare metals

In conventional glass sensors, rare metals are used for the sensor electrodes, but now we are using high-definition printing technology to form electrodes without using rare metals.