Environmental Report 2019

Measures against Climate Change

The fight against climate change is a crucial global issue that requires the further involvement of each and every person and organization.The JAE Group in Japan is working to address climate change through environmental awareness training, production–related measures, and measures at plant facilities.

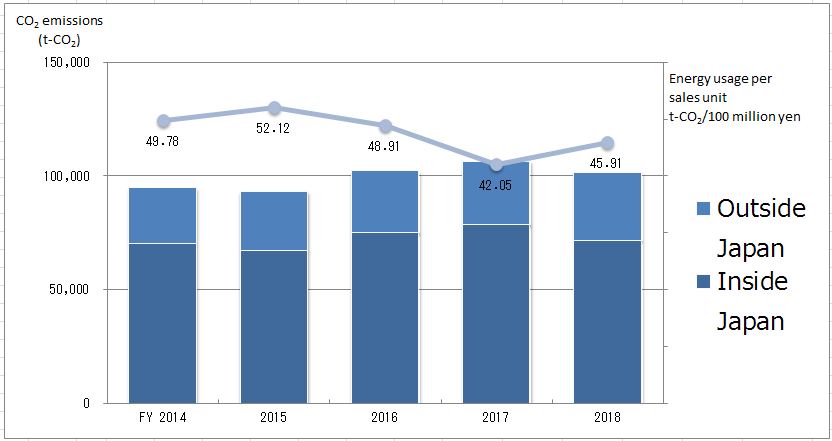

Amount of Carbon dioxide Emitted by the JAE Group in Japan

Total carbon dioxide (CO2) emissions of the JAE Group in Japan in fiscal 2018 were 72,075 tons, down year on year, but emissions per unit of sales increased.The main cause was the effect of production volume. We will continue to further promote energy saving in infrastructure and production equipment, and to carry out efficient production while monitoring total CO2 emissions and emissions per unit of sales.

| CO2 emissions volume by energy usage |

※Energy usage per sales unit is shown as unit of CO2 emissions in Japan and overseas, and consolidated net sales (unit: t-CO2/100 million yen)

※The equivalency factor for CO2 emissions due to energy use is the value published by the Federation of Electric Power Companies. In fiscal 2018, the fiscal 2017 result (0.496 ton-CO2/MWh) is being used.

Status of progress toward uniform goals in the electrical and electronics industries

The JAE Group in Japan participates in the electrical and electronics industries’ Action Plan for Achieving a Low Carbon Society and is progressing toward the goal of a 1% annual average energy efficiency improvement in production processes through 2030.Although total energy usage is increasing in line with higher production volumes, we have curbed energy usage per unit by taking steps to contribute to the fight against climate change.

In fiscal 2018, the improvement rate was 27.22% on a per-unit of energy basis, surpassing the goal of 5.85%.

Status of Response to Tokyo Cap-and-Trade Program

The Akishima Plant has an obligation to cut greenhouse gas emissions by an annual average of 15% during the second phase of the plan from fiscal 2015 to fiscal 2019.Emissions in fiscal 2018 were down 20.7% from the baseline year and we achieved our 15% annual reduction target. We expect to achieve our obligation to reduce greenhouse gases during the second phase of the plan.

We will keep working to do our part in the fight against climate change.

Fiscal 2018 Energy Conservation Case Studies

Energy conservation in plant facilities

Infrastructure-related

- Plant facilities

- Reduction of loss by replacing substation transformer (JAE)

•Reduction of 10,575 kWh/year by replacing two substation transformers with high-efficiency transformers

•Reduction of 2,457 kWh/year by replacing the substation transformer at NLC No. 2 Center with a high efficiency transformer (Top Runner II)

- Compressor upgrade and adjustment (YAE)

Reduction of 182,636 kWh/year by replacing the compressor with an inverter and adjusting the pressure

- Replacement of air conditioning equipment and cooling chiller (SAE)

Reduction of 19,000 kWh/year by replacing two air conditioning units and one cooling chiller used for impact tester

- Alleviation of burden on air conditioning by operating unused local exhaust devices (YAE)

Reduction of 75,336 kWh/year by using two local exhaust devices to boost exhaust heat in the molding room and alleviating the burden on the air conditioning

- Reduction of loss by replacing substation transformer (JAE)

- Lighting

- Upgraded to LED lighting (JAE, YAE)

•Upgraded the ceiling lighting of the No.3 Plant to LED lighting (JAE)Reduced 43,440 kWh/year by upgrading 450 lights

•Upgraded ceiling lights on 1st floor lobby of office building to LED lighting (JAE)Reduced 3,696 kWh/year by upgrading 20 lights

•Upgraded stairway and corridor guide lighting with LED lights (JAE)Reduction of 9,711 kWh/year by upgrading 28 lights

•Upgraded bathroom and locker room lighting with LED lights with motion sensors (JAE)Reduced of 18,370 kWh/year by upgrading ceiling lighting in 6 bathrooms and 10 locker rooms

•Upgraded NLC No. 4 Center to LED lighting (JAE)Reduced 8,816 kWh/year by upgrading two ceiling lights on the 2nd floor

•Upgraded the production area ceiling lighting to LED lighting (YAE)Reduced 34,085 kWh/year by upgrading 360 lights in the production area that operate 24 hours a day

1st floor ceiling LED lighting of office building 1 Office building stairway guide LED light - Switched from mercury lighting to LED lighting (JAE)

All 106 ground lights containing mercury (a harmful substance) were upgraded with 66 lights (reduction of 40,483 kWh/year) in fiscal 2017, 24 lights were upgraded in fiscal 2018 (reduction of 744 kWh/year), and the remaining 16 lights are to be upgraded in fiscal 2019.

- Upgraded to LED lighting (JAE, YAE)

- Production equipment related

- Attachment of insulation covers to molding machines (HAE, YAE)

Attached insulation covers to molding machine cylinders. HAE attached 44 covers for a total of 169 units (total reduction of 264,000 kWh/year), YAE attached 2 covers for a total of 12 units (total reduction of 28,600 kWh/year).

- Reduced power consumption changing to vacuum pump (YAE)

Reduced 182,636 kWh/year by changing from a plant air drive to a vacuum pump drive

- Converted to a blowerless high-speed press (YAE)

Reduced 6,718 kWh/year by converting 11 high-speed presses to blowerless

- Cut off drainage air (YAE)

Reduced 96,360 kWh/year by continuously cutting off the air of equipment drainage

- Attachment of insulation covers to molding machines (HAE, YAE)

- Activities of overseas production bases

- Lights with sensors (JAE OR)

Participated in the Energy Trust SEM (Strategic Energy Management) program, for example, installed LED lighting for all warehouse lighting, which automatically turns off after five minutes if movement is not detected, and lights up if motion is detected

- Reduced energy consumption through various measures (JAE TJ)

Reduced energy consumption by 1.7%/year through the following measures:

-Reviewed air conditioning leaks in facilities

-Replaced 50 W and 100 W compressors

-Improved lighting operation of equipment areas, living rooms, etc. using the alert poster shown in the diagram below

- Reduced energy consumption through various measures (JAE TW)

Reduced energy consumption by 580 kWh/year through the following measures:

-Replaced 40 W light in office of the No.1 Plant with 18 W light

-More strongly promoting power conservation and develop the habit of turning off lights

- Reduced energy consumption through various measures (JAE WJ)

Reduced electricity costs by about 353,601 yuan/year through the following measures:

-Gathered and organized related data

-Managed temperature, humidity, and ventilation

-Maintained facilities/equipment, improved operating rate

-Controlled the number of air processors according to air supply

-Shut down equipment that is not being used

Monitoring of facility

- Reduced energy consumption through various measures (JAE WX)

Reduced CO2 emissions by 16.6 kg/yuan/year through the following measures:

-Routinely checked for compressed air leaks

-Controlled temperature of office rooms

-Installed lighting switch on worktables of production site

-Improved air supply by installing an open air treatment system in the assembly area of the old plant

Open air treatment system and the temperature control switch

- Lights with sensors (JAE OR)

- Logistics related

Reduction of CO2 with modal shift transportation

Continuously operating CO2 reduction with modal shift transportation

Convert main line freight transportation into sea or rail transport capable of mass transportation.

⇒24.95 tons/year reduction in CO2 emissions (versus truck transportation)Eco Rail Mark

Activities to Increase Awareness of Measures to Fight Climate Change

Introduced here are several fiscal 2018 efforts made to increase awareness of climate change measures.- No Driving Day

- Eco-driving training

- Clean up campaign around each work site, and other activities

(For details, see the Environmental Education section)

- Cool Biz (May 7 through October 31)

- Warm Biz (November 1 through March 31)

July 7: “Tanabata Lights Down” (Cool Earth Day)