Environmental Report 2010

Eco-friendly Products

Eco-friendly Design

When introducing product designs and new manufacturing methods, all processes are assessed, from design to manufacturing and shipment. In addition, the introduction of a new chemical substance or piece of equipment, construction work, increased waste volume, and other changes require an environmental safety assessment under JAE's in-house pre-assessment system. In this manner, JAE is practicing business activities that are environmentally friendly.The following table shows the activity status of the company's environmental safety assessments.

Click the Chemical Substance Management/PRTR Information link on the sidebar for the explanation on chemical substances.

■JAE Akishima Plant

| Year | 2007 | 2008 | 2009 |

| Number of assessments | 426 | 319 | 240 |

Product Assessment

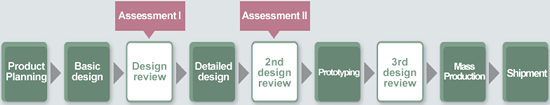

At the product development and design stage, products are pre-assessed, taking into consideration features such as resource conservation, energy saving, and recycling. In examining designs, the assessment by the division assigned to product development (Assessment I) is followed by another independent assessment (Assessment II) to decide whether the work should proceed to the next phase.

Examples of Assessment Items

| Downsizing | Recycle | Ease of disassembly and treatment | Safety and environmental preservation | Ease of recovery and transportation |

| Longer service life | Power conservation | Packaging and crating | Provision of information | Protection of intellectual property rights |

Assessment of Production Methods

To lower the environmental impact of manufacturing processes, new or modified processes are pre-assessed to determine their environmental impact.

Product Efforts

Environmentally friendly efforts are underway, starting from the design stage, in order to reduce environmental impacts at each stage (product manufacturing, use, and disposal).In product design, materials with low toxicity are being used and products are being made more energy efficient, and in mold design, too, efforts are being made, including improving the utilization rate of mold materials and increasing the life of the molds themselves. The environmentally friendly efforts for each product are introduced below.Connectors:

●f-CONNECT (LGA socket for supercomputers)

(1)RoHSdirective-compliant product

No materials prohibited by RoHS regulations are used.

(2)Spacing-saving design for areas where clients mount components

Enables 5,475 terminals while still maintaining high precision and low height connections.

(3)Resource conservation

The weight-bearing structure was simplified by enabling a low contact pressure one-tenth the level of before. In addition, solder-less connections are also being achieved.

(4)Halogen-free products

No halogen-based fire retardants are being used.

Interfaces/Solutions:

●EMC directive compliance (LCD touch panels)

(1)RoHS-compliant products

Along with using lead-free solder, the screws used are surface treated with hexavalent chromium.

(2)Energy savings

Energy consumption is being cut by 15% or more over previous products by revising power supply circuits and switching to LED backlighting, thereby improving energy efficiency.

(3)EMC compliance

EMC directives are being met and the CE mark is being acquired.

Aircraft

●FOG attitude measurement system (JCS7402 series)

(1)RoHS-compliant product

The product developed in 2005 underwent a design revision to make it RoHS compliant. The entire product was made RoHS compliant, including its electronic substrate and gyro.

(2)Use of lead-free solder

Lead-free solder is now used for everything, including electronic substrates and wiring. In addition, products now use lead-free electroless nickel plating.