Environmental Report 2018

Measures against Climate Change

The fight against climate change is a crucial global issue that requires the further involvement of each and every person and organization.The JAE Group in Japan is working to address climate change through environmental awareness training, production–related measures, and measures at plant facilities.

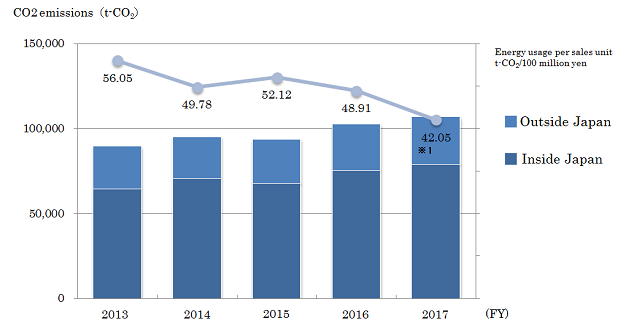

Amount of CO2 Emitted by the JAE Group in Japan

The total CO2 emissions of the JAE Group for fiscal 2017 amounted to 78,801 tons*1, an increase over the previous fiscal year.The main factor behind the increase of greenhouse gas emissions in the past five years was higher production. The improvement in emissions per unit of net sales in fiscal 2017 was due to efficient production.

| CO2 emissions volume by energy usage |

*Energy usage per sales unit is shown as unit of CO2 emissions in Japan and overseas, and consolidated net sales (unit: t-CO2/100 million yen)

*The equivalency factor for CO2 emissions due to energy use is the value published by the Federation of Electric Power Companies. In fiscal 2017, the fiscal 2016 result (0.516 tons-CO2/MWh) is being used.

*1:Fixed on August 7, 2018

Status of progress toward uniform goals in the electrical and electronics industries

The JAE Group in Japan participates in the electrical and electronics industries’ Action Plan for Achieving a Low Carbon Society and is progressing toward the goal of a 1% annual average energy efficiency improvement in production processes through 2030.Although total energy usage is increasing in line with higher production volumes, we have curbed energy usage per unit (use cursor to view definition) by taking steps to contribute to the fight against climate change.

In fiscal 2017, the improvement rate was 33.11% on a per-unit of energy basis, surpassing the goal of 4.90%.

Status of Response to Tokyo Cap-and-Trade Program

The Akishima Plant has an obligation to cut greenhouse gas emissions by an annual average of 15% during the second phase of the plan from fiscal 2015 to fiscal 2019.Emissions in fiscal 2017 were down 9.2% from the baseline year, but this fell short of the 15% annual reduction target. However, we expect to achieve our obligation to reduce greenhouse gases during the second phase of the plan. The reason for the increase in greenhouse gas emissions was the expansion of production facilities and other factors. We will keep working to do our part in the fight against climate change.

Fiscal 2017 Energy Conservation Case Studies

●Infrastructure-related(1) Lighting

Switching from mercury lighting to LED lighting (JAE)

Out of 106 lighting units including mercury (a harmful substance), 61 units (37,400 kWh/year) were completed by fiscal 2016. In fiscal 2017, a 3,033 kWh/year reduction was achieved with 5 units. The remaining 40 units will be converted to LED lighting.

The arena lighting (metal halide lamps) in the gymnasium will be upgraded to LED lighting (JAE)

Reduced power consumption by 34,249 kWh/year with a total of 30 units.

- Upgraded building emergency lighting to LED lighting (JAE)

Reduced power consumption by 13,634 kWh/year by upgrading 78 units of constant light (about 840 units). - Upgraded bathroom lighting to LED lighting with motion detectors (JAE)

Upgraded four locations and reduced power consumption by 4,729 kWh/year. - Upgraded bicycle parking lighting to LED lighting (JAE)

Converted all 34 fluorescent units to LED units and reduced power consumption by 960 kWh/year. - Converted to LED lighting (HAE)

Reduced power consumption by 38,000 kWh/year by converting external and internal lighting to LED lighting and installing timers on external lighting. - Converted lighting to LED lighting (YAE)

Converted 372 units to LED units and reduced power consumption by 34,000 kWh/year. - Converted lighting to LED lighting (SAE)

Converted 45 ceramic metal halide lamps to LED lighting and cut power consumption by 32,000 kWh/year.

(2) Utilities-based activities

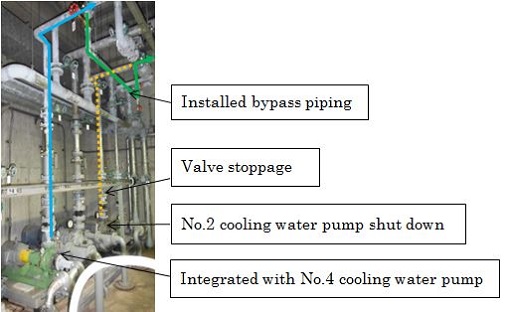

- Conserved energy by integrating cooling water pumps for production (JAE)

Installed bypass piping, took down one pump and cut power consumption by 94,600 kWh/year.

- Loss reduction due to substation transformer (2 units) upgrade (JAE)

Power consumption reduced by 11,380 kWh/year by upgrading to two high-efficiency transformers. - Improved cooling efficiency with reexamination of ventilation method (YAE)

Cut power consumption by 75,000 kWh/year by utilizing local exhaust equipment to boost exhaust heat of molding room. - Upgrade of air conditioning equipment (SAE)

Cut power consumption by 16,000 kWh/year by upgrading 2 units, the inverter control and unit control.

●Production equipment related

(1) Attachment of insulation covers to molding machine cylinders (HAE, YAE)

Systematically working on insulation at HAE and YAE. At HAE, achieved 53 units total: a 39,552 kWh reduction per year; and at YAE, 3 units total: 5,600 kWh per year. Therefore, as a side effect, we also expect to reduce the air conditioning load caused by a decline in thermal release from the equipment to the work area.

(2) Air energy saving

- Air leakage patrol (JAE)

Cut 70,950 kWh/year by repairing 15 air leaks. - Air energy saving (YAE)

Cut 337,000 kWh/year by changing the method for extracting products, changing air drainage method, and intermittently blowing air.

Cut 10,129 kWh/year by making the following changes to the production process.

- Cut 7,413 kWh/year by changing processing method.

- Cut 2,716 kWh/year by reducing processing time.

Activities to Increase Awareness of Measures to Fight Climate Change

Introduced here are several fiscal 2017 efforts made to increase awareness of climate change measures.● Environment Month (June 1 to June 30)

Environment Month publicity and a wide range of Environment Month activities were held at each site.

Campaign to stop automotive idling

No Driving Day

Eco-driving training

Clean up campaign around each work site, and other activities

● General education about ISO14001: 2015 revisions and environmental education concerning energy saving(July 4 through August 30)

All employees of the JAE Group in Japan took part in e-learning.

(For details, see the Environmental Education section)

● Warm Biz and Cool Biz

Cool Biz (May 8 through October 31)

Warm Biz (November 1 through March 31)

● Participation in energy-saving "Lights Down" campaign (June 21 and July 7)

On summer solstice and "Tanabata" nights, for the two hours from 8 to 10 pm, called "Lights Down" time, as many lights as possible are switched off at each work site and workers do the same in their homes.

June 21: Summer solstice lights down (black illumination)

July 7: "Tanabata Lights Down" (Cool Earth Day)