Environmental Report 2016

Chemical Substance Management

Improving chemical substance management

In consideration of workers' safety and health, and looking to lower environmental impact, we are making efforts to improve the management of chemical substances. Here we introduce initiatives undertaken by the JAE Group in Japan, and individual case studies about sites around the country.Across the JAE Group in Japan

♦GHS (*use the cursor to view definition) symbol education

To prevent disasters, secure safety, preserve the environment, and provide information to users, JAE conducted e-learning concerning GHS symbols for operators and managers of chemical substances. This education was provided to 512 people at the JAE, HAE, YAE, FAE and SAE sites. JAE continuously strives to provide information on dangerously toxic substances.

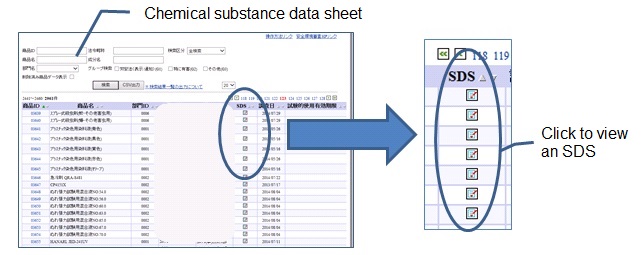

♦Sharing chemical substance information

The JAE site database of chemical substances, given its many product categories, is available at four sites around Japan. By sharing the SDS information, and with the goal of streamlining the obtaining of SDS, JAE has begun an initiative to provide chemical substance safety data sheets (SDS).

JAE Site

♦Streamlining the system to register chemical substances

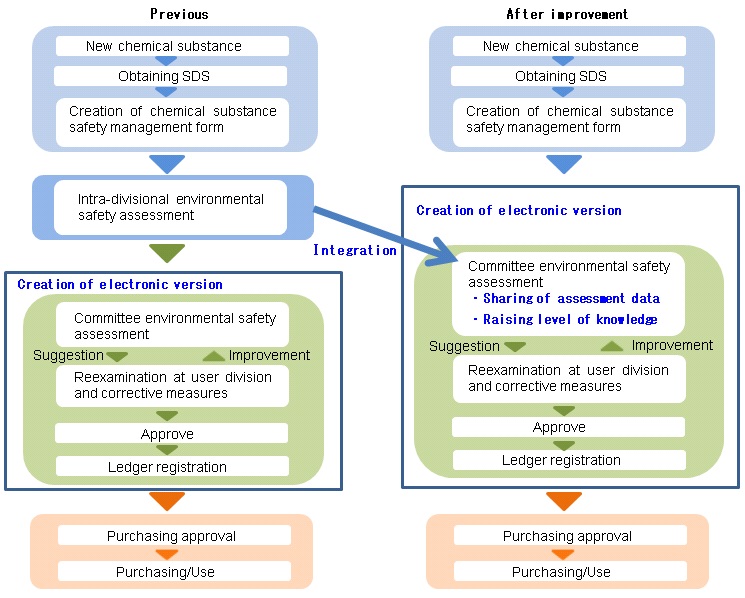

First, here is an explanation of chemical substance registration.

The introduction of a new chemical substance or piece of equipment, construction work, disposal of waste, or unscheduled operations thought to present safety problems or another issue, requires an environmental safety assessment under JAE's in-house pre-assessment system, as shown in the flowchart below. With regard to the use of chemical substances, a chemical substance safety management form is prepared, and assessment is made, with the entry of requisite information on items including transport, storage, handling, and disposal of chemical substances. Given this, chemical substances can only be purchased if they pass this assessment.

The environmental safety assessment at JAE sites, comprising internal division assessments and committee assessments, has since 2012 seen an electronic version of the committee assessment for increased efficiency. In fiscal 2015, while guaranteeing the trustworthiness of the assessment, operations were improved with the integration of division and committee assessments in order to further enhance efficiency and raise the level of information sharing and knowledge among assessment team members (refer to the chart below).

■Pre-assessment flowchart for new chemical substances following the environmental safety assessment

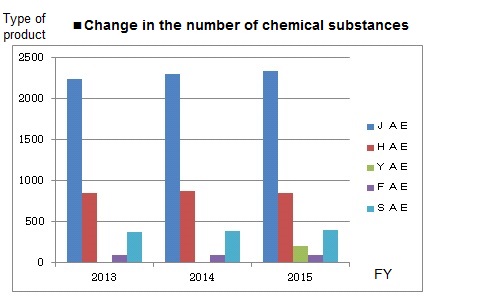

Monitoring registration of chemical substance product types

Change in the number of chemical substance product types at five sites in Japan is as shown in the below graph. The reason that the JAE site has more chemical substances than other sites is because it is not only involved in production, but is also a development plant and uses chemical substances for testing. YAE has begun to aggregate data from 2015.The JAE Group continues to work hard to cut types of unnecessary chemical substances and to reduce the volume of chemical substances, as shown below.

Reduction of Chemical Substances

As in the previous fiscal year, in fiscal 2015 each production site selected specific chemicals and worked to reduce the amount used in order to reduce its environmental impact. The main points of the activities for reducing the use of chemicals in fiscal 2015 are shown below, and these reduction efforts will continue in the coming years.Note that the letters in parentheses, such as JAE, HAE, YAE, FAE and SAE, are abbreviations denoting sites that carried out these activities.

- Reducing the metal used for deposition in gold plating (JAE)

- Reducing chemical usage by revising the plating production process (HAE)

- Reducing chemical usage by cutting volume of replacement and newly purchased chemicals (YAE, SAE)

- Reducing the amount of VOC-emissions by improving the airtightness of containers and promoting the use of non-VOC cleaning solutions (JAE)

PRTR Data

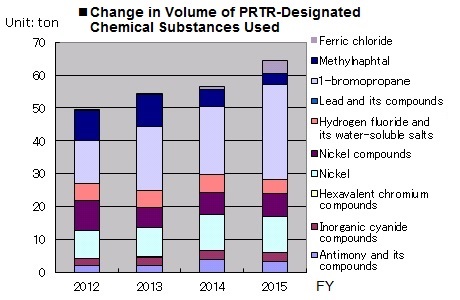

The graph below shows the change in the amount of chemicals subject to the PRTR Law (*use cursor to view definitions) that was used by five domestic manufacturing companies.Fiscal 2015 was witness to increases in ferric chloride used in 1-bromopropane, primarily used in cleaning agents, and in liquid waste treatments associated with plating. This was in line with increased production volumes. There was also a reduction in the volume of methylnaphtal, a component of heavy oil used in boilers, owing to removal of boilers and switching to air-cooled heat pumps, which cut crude oil. The JAE Group's efforts to identify trends with regard to the handling of PRTR volumes are ongoing.

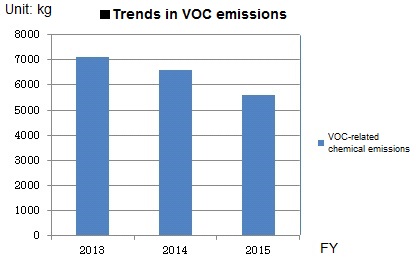

VOC Information

The JAE Group has been reducing VOC-related chemical emissions each year, primarily of alcohol and other cleaning fluids. This is on account of improving the airtightness of containers and in promoting the use of non-VOC cleaning fluids. The total volume of chemical emissions of VOCs and related substances (use cursor to view definitions) for five combined sites in Japan is shown in the below graph. We will continue to monitor after fiscal 2015 as we strive to reduce chemical emissions into the environment.