Environmental Report 2016

Measures against Climate Change

The fight against climate change is a crucial global issue that requires the further involvement of each and every person and organization. The JAE Group is working to address climate change through the teaching of environmental awareness, production-related measures, and measures at plant facilities, and it has set definite objectives and targets for its environmental activities.Amount of CO2 emitted by the JAE Group in Japan

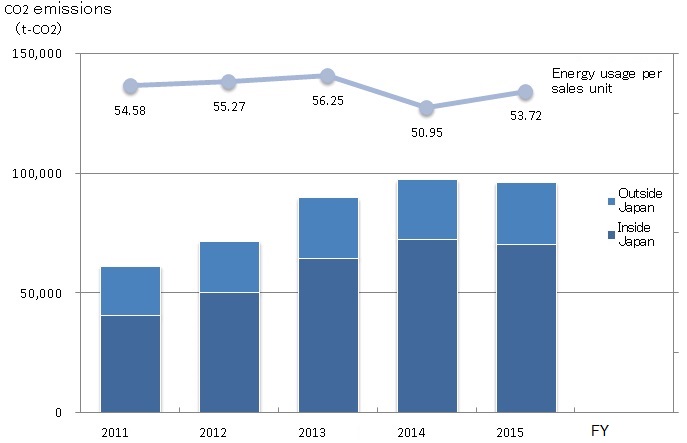

Total CO2 emissions of the JAE Group for fiscal 2015 amounted to 96,423 tons, essentially unchanged compared to the previous fiscal year. The main factor behind rising levels of greenhouse gas emissions in the past five years has been the stronger production structure at the HAE and YAE sites, which are the principal manufacturing bases for connectors. In addition, deterioration in the emissions per unit of net sales in fiscal 2015 was primarily attributable to a dramatic drop in orders starting in the second half. However, this caused special attention to be placed on the issue of building efficient infrastructure that would not be shaken by increases or decreases in production, or other factors.| CO2 emissions volume by energy usage |

*Energy usage per sales unit is shown as unit of CO2 emissions in Japan and overseas, and consolidated net sales (unit: t-CO2/100 million yen)

*The equivalency factor for CO2 emissions due to energy use is the value published by the Federation of Electric Power Companies. In fiscal 2015, the fiscal 2014 result (0.554 tons-CO2/MWh) is being used.

Status of progress toward uniform goals in the electrical and electronics industries

The JAE Group in Japan participates in the electrical and electronics industries' Action Plan for Achieving a Low Carbon Society and is progressing toward the goal of a1% annual average improvement on a per-unit of energy basis through 2020.

Total energy usage is increasing in line with higher production volumes, but measures to combat global warming put in place at all sites have led to improved energy usage per unit (*use the cursor to view definition). In fiscal 2015, the improvement rate was 2.99% on a per-unit of energy basis, surpassing the goal of 2.97%.

Status of Response to Tokyo Cap-and-Trade Program

The Akishima Plant has an obligation to cut greenhouse gas emissions by an average of 15% during the second phase of the plan from fiscal 2015 to fiscal 2019. Emissions were cut by approximately 19% from the baseline standard of fiscal 2015, exceeding the reductions set forth in the initial plans.Fiscal 2015 Energy Conservation Case Studies

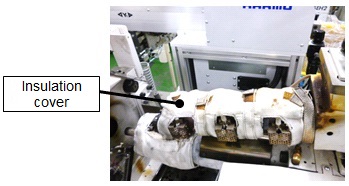

Case Study: Energy Conservation in Production- Energy conserving molding machines

Insulation covers are being attached to injection machine cylinders. By doing so, a roughly 7% cut in energy consumed, per machine, can be achieved. Currently, covers have been attached to over 50 machines.

- Air conditioning heat source overhaul (FY2014-FY2016 three-year plan's second-stage overhaul)

In line with facility upgrades, JAE upgraded equipment from water-cooling systems to energy-saving-type air-cooling systems. In addition, it disposed of the turbo refrigeration units that had been used in the water-cooling systems, saving space in the installation area.

- Switching from mercury lighting to LED lighting

In addition to saving energy, preparing for the 2020 discontinuation of the manufacture of specified mercury-added products, which include the harmful substance mercury, out of the total 122 lighting units at the JAE site (Akishima Plant), 20 units (16,100 kwh reduction) had been replaced by fiscal 2014, and in fiscal 2015, 12 more units were replaced (11,000 kwh reduction). The remaining 90 units are scheduled to be systematically upgraded by fiscal 2019.

- Energy-efficient, always-on lighting

JAE has upgraded from fluorescent to LED-type guidance lighting.

The upgrading of all 211 units at the JAE site (Akishima Plant) has been completed. In fiscal 2014, 112 units (7,850 kwh reduction) were upgraded, and in fiscal 2015, the remaining 99 units were upgraded.

- Energy-saving lighting equipment

The FAE site upgraded from fluorescent lighting to highly efficient fluorescent or LED-type lighting. In fiscal 2015, all 122 fluorescent lights in the discharge machining area, where there are lengthy usage times, were upgraded to 50 highly efficient fluorescent lights and 72 LED lights (total of 15.7 kwh reduction).

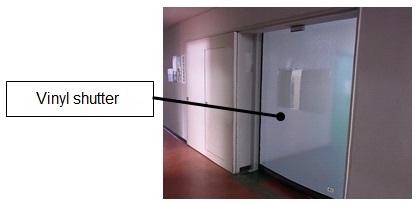

- Improvement to air conditioning environment

Installation of vinyl shutter in the plant's internal hallways

(restricting entry of cold winter air from hallway areas to work areas)

Along with an upgrade to an energy-saving type, the number of units installed was increased from five to nine, which increased the level of convenience for cafeteria users. The units are operated with precise timer function settings.

- Energy-saving initiatives associated with Comprehensive Assessment and Testing Building construction

Along with the construction of a Comprehensive Assessment and Testing Building, we undertook construction that incorporated energy-saving technologies for the following items.

Air conditioning equipment, ventilation equipment, lighting equipment, water heating system (tea dispenser), elevator equipment, exterior walls, window glass, and roofing

Operating a total of 14 temperature resistant evaluation machines, and in line with the emission conditions, proper control of air supply flow rate using inverter control.

Activities to increase awareness of measures to fight global warming

Introduced here are several fiscal 2015 efforts made to increase awareness of global warming measures.- Environment Month (June 1 to June 30)

Environment Month publicity and a wide range of Environment Month activities were held at each site.

・Campaign to stop automotive idling

・No Driving Day

・Eco-driving training

・Clean up campaign around each work site, and other activities - Environmental education concerning energy saving (July 1 through August 7)

All employees of the JAE Group in Japan took part in e-learning.

(For details, see the Environmental Education section). - Warm Biz and Cool Biz

Cool Biz (May 7 through October 30)

Warm Biz (November 2 through March 31) - Participation in energy-saving "Lights Down" campaign (June 22 and July 7)

On summer solstice and "Tanabata" nights, for the two hours from 8 to 10 pm, called "Lights Down" time, as many lights as possible are switched off at each work site and workers do the same in their homes.

1. June 22: Summer solstice lights down (black illumination)

2. July 7: "Tanabata Lights Down" (Cool Earth Day)