Environmental Report 2023

Reduction of Materials and Resource Usage

Reducing Usage of Materials and Resource Usage

We are working hard to reduce the amount of material that becomes waste after being introduced into the manufacturing phase. In addition to reducing and effectively utilizing natural resources, we also pursue the reduction of energy use, greenhouse gas emissions, and costs from material manufacturing to the processing of products.See below for information on our efforts for the effective use of key materials at each site.

●Efforts at JAE

To reduce the amount of material used in machining, JAE is working to purchase materials in ideal sizes. In order to reduce the volume of gold used in gold plating in production, JAE is making ongoing efforts to implement efficiency improvements such as the management of the proper metal plating area and its thickness speeding up the process. At the same time, it utilizes reusable parts of production equipment and pursues the effective use of resources and the reduction of material and capital investment costs.

●Efforts at HAE

HAE is reducing the amount of materials used by reducing the width of metal materials used in presses and reducing pin protection materials. Molding materials are being reduced by downsizing unnecessary spoolers/runners (*use cursor to view definitions) that are discharged when extracting molded products, improving the number, mold shape, and positioning of gates (*use cursor to view definitions) when designing molds, and using hot runners and pulverizing equipment with spoolers/runners. We continue to improve the value ratio by reducing the amount of newly purchased input materials through the use of recycled materials and by reviewing materials that are subject to value-added disposal, which also helps to reduce waste.

To reduce the amount of gold used in gold plating, HAE is constantly making efficiency improvements such as in proper plating area as well as thickness management and speeding up the process. This has led to significant cost reductions. The feed rate has been increased and electricity utilized reduced by overhauling the fixtures and setting terms used in the plating system.

●Efforts at YAE

We are continuously promoting measures to reduce the amount of materials used by downsizing press molds, revising the width of metal materials used in presses, investigating the material yield, verifying and setting the minimum number of turns for plating, and performing early detection of key sample abnormalities. In addition, increasing the rate of reuse of molding materials, reducing input materials by promoting closed-loop-recycling of product waste, and cutting down on the volume of materials used by making spoolers/runners more compact, result in significant CO2 reductions.

●Efforts at FAE

Efforts to improve the reuse rate for copper alloy electrode material used in the manufacturing process for mold parts (discharge machining) are contributing to a reduction in the quantity of material used, electric power, and the metal waste generated. It also introduced a special processing machine for cutting the plate material to reduce the margin for grinding, enabling effective use of materials.

●Efforts at SAE

The SAE site continues to focus on reducing cutting processes. These efforts contribute to reduced metal waste, as well as lower CO2 emissions during material production.

Conservation of Water Resources

Japan may appear to be a country with abundant water resources, but it is actually said to be one of the world’s largest importers of virtual water (*use the cursor to view definition). Around the world, we see explosive population growth as well as drought and other abnormal weather conditions that result in many people being unable to obtain one-tenth of the daily water that a person requires.

The public expects companies to take initiatives to ensure the sustainable use of water resources. This is seen as a global issue, like others addressed by the Sustainable Development Goals (SDGs) adopted at the United Nations in 2015. As a responsibility of a manufacturer with a plating line that uses a large amount of water, we have continued to report our work to preserve water resources since our 2015 environmental report.

2015: Water input volume in sales per unit based on water conservation

2016: Water resource circulation balance was put into a visually readable format at JAE

2017: Water Risk Assessment (using WRI Aqueduct) at JAE compared with CDP, and water resource management goals and PDCA cycle compared with SDGs

Since 2018: Water data survey of the supply chain/Understanding water consumption

Here are reported examples of reducing water usage and the status and challenges of new initiatives.

Examples of Reducing Water Usage

We will present some examples of activities conducted by the JAE Group in Japan and overseas to reduce water usage through the protection of forests to conserve water resources, and the cleaning of rivers and seacoasts. (Items in parentheses are abbreviations of production site names.)

- Water saving in production: Recycling water in the connector product plating line (JAE, HAE, JAE OR, JAE TW), on/off controls for water usage on each cleaning line, installing an evaporation prevention cover (JAE OR), changing water required for cleaning the plating line from running water to mist blown water (HAE), circulating pure water used for cooling chiller (HAE), and recycling water used for machinery and equipment (JAE TW). Also limiting users in processes where large volumes of water are required for cleaning and creating specialized faucets that are opened with keys (JAE WJ).

- Water saving in lifestyle: Adjusting water volume used in air conditioning cooling towers, recycling wastewater, using rainwater for toilets (JAE PH), using cooling tower drain water for toilets (JAE PH), changing from buried pipes that supply water for living to above-ground piping for the early detection of leaks and repair (JAE PH), educating about water saving using labels on water conservation in restrooms (JAE PH, JAE WX), adjusting the water volume discharged from faucets (JAE WX), installing meters showing how much water is used in cooling towers (JAE WX), raising water conservation awareness, and adopting water-saving sensors (JAE WJ).

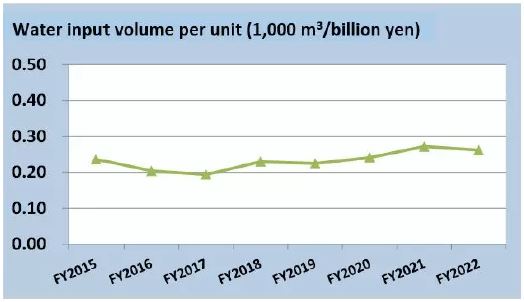

- Although the water input volume per unit is gradually decreasing due to the activities shown in the reduction example above, it appears that we need to take further steps to improve both production efficiency and reduction measures to prevent the impact of external turmoil such as deteriorating production efficiency caused by the COVID-19 pandemic that started in fiscal 2020. (The graph displays water input volume per unit of sales.)

Survey on water consumption and water replenishment rate

While considering policies to further reduce water usage, we surveyed consumption in the water circulation cycle at worksites. After surveying the amount of evaporation from production and air conditioning equipment, the amount of food and drink consumed at the Company’s welfare facilities, the amount of watering of areas of greenery, and the amount of evaporation from other facilities, we found that there was a difference between the estimates and meter readings in the amount of evaporation from the air conditioning cooling towers.

Just as last year, as a result of checking the water supply, the difference was 5.2 times. A difference of 4 to 7 times, depending on yearly weather conditions, was expected, but the ratio of consumption to input, although gradually declining, has not changed much for the past five years, and is about 13%.

In addition, the watershed is replenished by the JAE Group’s forests and the Akishima Plant’s rainwater infiltration tanks, and the replenishment rate to consumption has reached an average annual rate of 200%.

Below are the annual estimates of consumption by the domestic Group for the past five years, the breakdown for fiscal 2022, and the replenishment rate.

Measures to reduce water usage had a major effect on air conditioning equipment, so as an effective measure, we will install meters whenever possible to monitor and reduce the amount of evaporation.

| FY | Consumption | Estimated evaporation/Measured value* | Consumption/Input | Replenishment rate |

| 2018 | 46,269 m3 | 4.4 | 14.1 % | 144 % |

| 2019 | 38,894 m3 | 6.5 | 13.3 % | 295 % |

| 2020 | 40,916 m3 | 5.3 | 12.8 % | 211 % |

| 2021 | 42,970 m3 | 5.1 | 12.6 % | 165 % |

| 2022 | 40,377 m3 | 5.2 | 12.3 % | 191 % |

| Evaporation from cooling/production | 96% | (*) Results of a comparison of air conditioning cooling towers where actual measurements were available. | ||

| Efforts for drinking water/food | 3.1% | |||

| Watering plants | 0.6% | |||

| Evaporation from water storage facility | 0.3% |

Contribution of the JAE Group Forest

Through the planting of Japanese cypress and broadleaf trees in the JAE Group Forest, we estimate that watershed replenishment is approximately 5,320 m3 per year.

Building a Sustainable World

Significance of the 2023 Environmental Report

Symbol of the Group's Environmental Policies

Scope of Reporting and Editorial Policy

Policies and Results of Environmental Activities

Environmental Management

- Implementation Status of the Environmental Management System

- Environmental Audits

- Environmental Education

- Environmental Risk Management

- Environmental Accounting

Engaging with Society

- Involvement with Biodiversity

- Supply Chain Management

- Eco-Friendly Products

- Social contribution activities

Initiatives to Reduce Environmental Impact