Environmental Report 2023

Eco-Friendly Products

Product-Related Efforts

Eco-friendly efforts starting from the design stage are underway in order to reduce environmental impact at each stage, from product manufacturing and use to disposal.In product design, materials with low toxicity are being used, and products are being made more energy efficient. And in mold design, other eco-friendly efforts are being pursued, including improving the utilization rate of mold materials and increasing the life of the molds themselves.

The eco-friendly efforts for each product are introduced below.

Examples of Eco-friendly Products

Connectors

AB10 Series

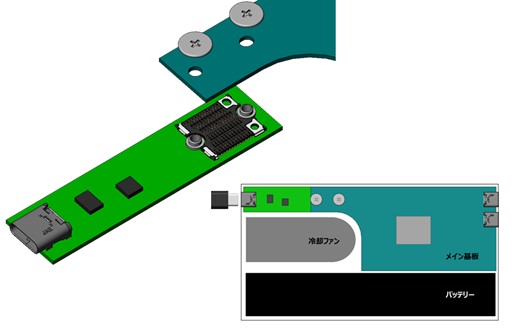

- Product concept: Improved repairability index By making USB charging ports, which are frequently inserted and removed and have a high risk of malfunction, easy for consumers to repair, the product reduces consumer electronics waste and helps improve the repairability index.

- Modularization of USBs without FPCsThe module substrate can be taken from the same sheet as the main substrate to reduce material loss and energy during processing.

- No special tools required:Its mating structure enables module replacement with just a common screwdriver.

- Low-temperature solder mountingThe product is suitable for low-temperature solder mounting, which reduces CO2 emissions in the mounting process.

Connector Business

KW07 Series for 200A fast charging

- 200A current CHAdeMO standard supports xEV fast chargingCompared to the existing KW1 Series, a significant increase in maximum current capacity up to 200A has been achieved. This enables EVs to be recharged in a short time span, thus helping to build a sustainable world.

- Resource saving through product designOptimization of material usage achieved by designing a smaller and lighter body through additional design optimization. Power consumption in manufacturing was reduced by simplifying the assembly method.

- Environmentally compliant specification (RoHS Directive compliant products)

The component materials are RoHS Directive compliant and environmentally friendly.

User Interface Solutions

Metal mesh film sensors (for capacitive touch panels)

- Significantly reduces energy consumption, and water and chemical usage through our proprietary printing process

Our proprietary roll-to-roll printing method prints material only on the spots required in product formation without waste. We have achieved an environmentally friendly production process that greatly reduces energy consumption and water and chemical usage, compared to ITO touch panels that use the conventional vapor deposition process. - Recycling of used ink

We are working to recycle used ink and make effective use of the materials used.

Building a Sustainable World

Significance of the 2023 Environmental Report

Symbol of the Group's Environmental Policies

Scope of Reporting and Editorial Policy

Policies and Results of Environmental Activities

Environmental Management

- Implementation Status of the Environmental Management System

- Environmental Audits

- Environmental Education

- Environmental Risk Management

- Environmental Accounting

Engaging with Society

- Involvement with Biodiversity

- Supply Chain Management

- Eco-Friendly Products

- Social contribution activities

Initiatives to Reduce Environmental Impact