Environmental Report 2023

- Return

- 19 / 19

Zero Emissions

The JAE Group makes effective use of resources by reducing general waste and consuming less paper, while promoting recycling and the sale of valuable resources through the exhaustive sorting of waste, such as scrap plastic and metal.

Zero Emissions Activities

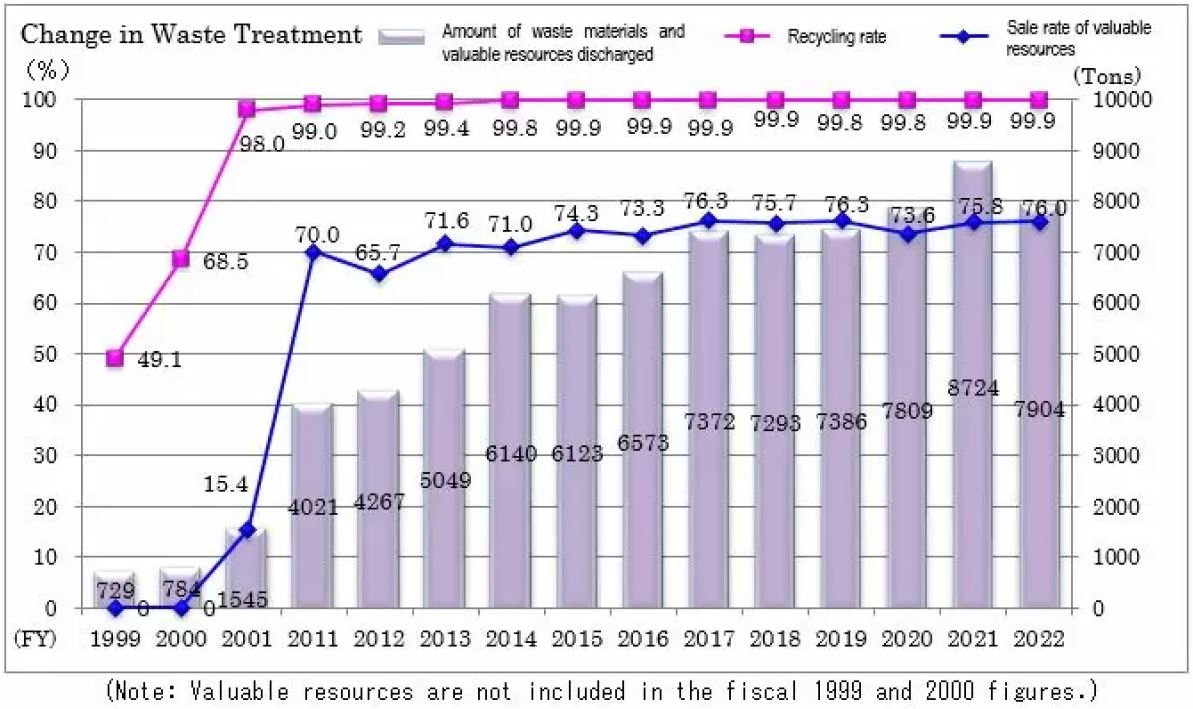

JAE achieved its recycling rate target of 99% in fiscal 2004, and with continuous effort since then, the level reached a high point of 99.9% in fiscal 2022, following a previous high of 99.8% in fiscal 2014.

We strive to reduce the waste disposal costs of all waste generated by selling metal waste and improving the quality of plastic recycling. The sale of valuable waste contributes to resource saving and the reduction of CO2 over the life cycle of products. The Group aims to achieve even higher rates of sales.

Note: The JAE Group defines zero emissions as achieving a recycling rate of 99.5% or higher for waste defined by local ordinances, excluding waste that is disposed of by incineration and simple landfills.

Efforts for Proper Disposal of Waste Materials

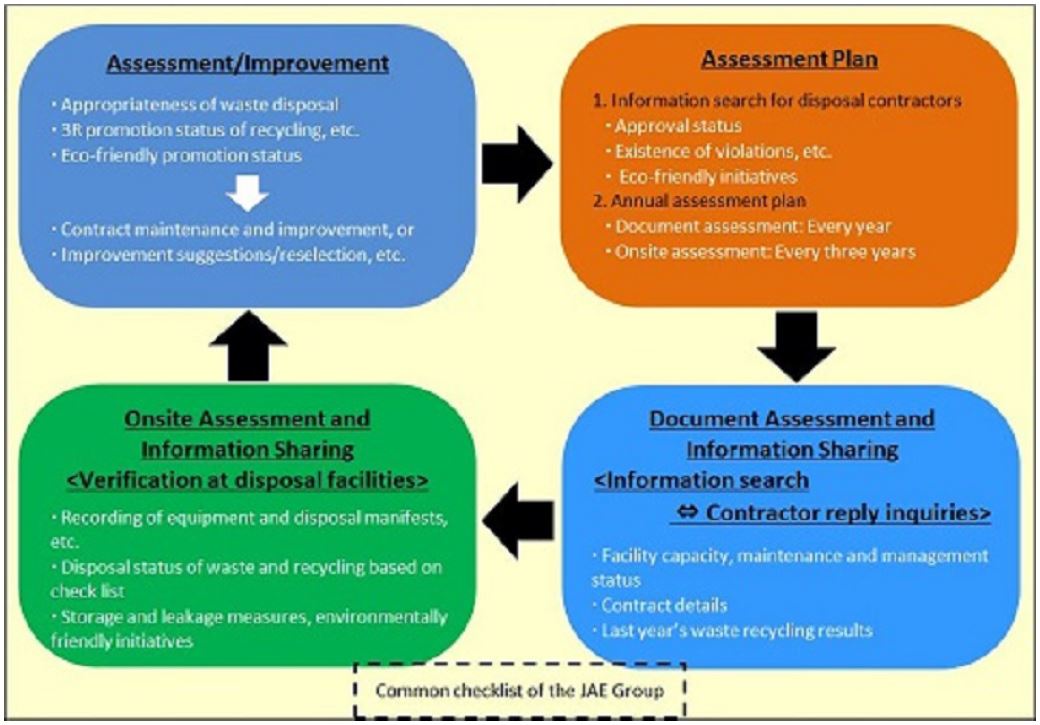

The JAE Group is implementing proper disposal of waste materials in accordance with Japan's Waste Management Law. The Group verifies the appropriateness of subcontractors that handle all types of industrial waste, general waste, and valuable resources at the time of contract signing and thereafter by periodically checking their licenses and performing on-site inspections.In fiscal 2017, we created a check list to clarify items to be checked and points to be changed for disposal contractors and to enhance communication with them.

Main Activities in Fiscal 2022

The main efforts to reduce wastes are shown below.

JAE also collaborates with partners throughout the supply chain to promote recycling by monitoring contractor compliance with the new plastics law and promoting recycling awareness.

Our waste education includes promoting understanding of the plastic waste problem and how waste causes environmental pollution, as well as information that can be put into daily practice.

- Return

- 19 / 19

Building a Sustainable World

Significance of the 2023 Environmental Report

Symbol of the Group's Environmental Policies

Scope of Reporting and Editorial Policy

Policies and Results of Environmental Activities

Environmental Management

- Implementation Status of the Environmental Management System

- Environmental Audits

- Environmental Education

- Environmental Risk Management

- Environmental Accounting

Engaging with Society

- Involvement with Biodiversity

- Supply Chain Management

- Eco-Friendly Products

- Social contribution activities

Initiatives to Reduce Environmental Impact