Environmental Report 2015

Measures against Climate Change

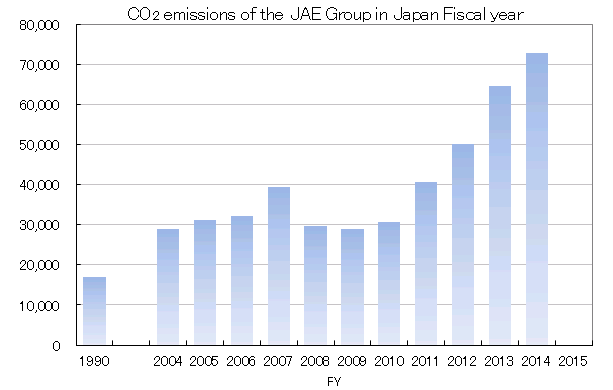

The fight against climate change is a crucial global issue that requires the further involvement of each and every person and organization. The JAE Group is working to address climate change through the teaching of environmental awareness, production-related measures, and measures at plant facilities, and it has set definite objectives and targets for its environmental activities.Amount of CO2 emitted by the JAE Group in Japan

Total CO2 emissions of the JAE Group in Japan for fiscal 2014 amounted to 72,664 tons, a 12.4% increase compared to the previous fiscal year.The primary cause of increased greenhouse gases was strengthened production structures at HAE and YAE sites, the main locations of connector production.

*The equivalency factor for CO2 emissions due to energy use is the value published by the Federation of Electric Power Companies. In fiscal 2014, the fiscal 2013 result (0.570tons-CO2/MWh) has been used.

Status of progress toward uniform goals in the electrical and electronics industries

The JAE Group in Japan participates in the electrical and electronics industries' Action Plan for Achieving a Low Carbon Society and is progressing toward the goal of a 1% annual average improvement on a per-unit of energy basis through 2020.Total energy usage is increasing in line with higher production volumes, but measures to combat global warming put in place at all sites have led to improved energy usage per unit (*use the cursor to view definition). In fiscal 2014, the improvement rate was a firm 8.98% on a per-unit of energy basis.

Status of Response to Tokyo Cap-and-Trade Program

The Akishima Plant has an obligation to cut greenhouse gas emissions by an average of 15% during the second phase of the plan from fiscal 2015 to fiscal 2019.Emissions were cut by approximately 23% from the baseline standard of fiscal 2014, exceeding the reductions set forth in the initial plans. This amount of reduction that surpassed the goal of the first phase of the plan is expected to be banked in the second phase.

Fiscal 2014 Energy Conservation Case Studies

Case Study: Energy Conservation in Production- Energy-conserving molding machines

injection machine cylinder

Energy Conservation at Plant Facilities

- Upgrading to energy-efficient air compressors

- Energy-efficient exterior lighting

- Energy-efficient, always-on lighting

Switching to LED-type guidance lighting

Activities to increase awareness of measures to fight global warming

In fiscal 2014 the following activities were conducted to increase awareness.(1) Environment Month (June 1 to June 30)

Environment Month publicity and a wide range of Environment Month activities were held at each site.

(2) Environmental education concerning energy saving

All employees of the JAE Group in Japan took part in e-learning.

(For details, see the Environmental Education section).

(3) Warm Biz and Cool Biz

Cool Biz (May 7 through October 31)

Warm Biz (November 1 through March 31)

(4) Participation in energy-saving “Lights Down” campaign (June 21 and July 7)

1. June 21: Summer solstice lights down (black illumination)

2. July 7: “Tanabata” lights down (Cool Earth Day)

(5) No Driving Day, Eco-driving training

1.No Driving Day

Employees of Japan Aviation Electronics Industry, Ltd.’s Akishima Plant who commute to work using their personal vehicles made ongoing efforts over the year to combat global warming, aiming to take public transportation twice a month.

FY14 commuting by personal vehicle: Total 2,944 people (average 245/month)

FY14 participating in No Driving Day two or more times a month: Total 737 people (average 61/month)

FY14 CO2 reduction 20.53 ton-CO2

(Cumulative reduction in fiscal year by participating in No Driving Day)

2.Eco-driving training