Environmental Report 2020

Chemical Substance Management

Improving Chemical Substance Management

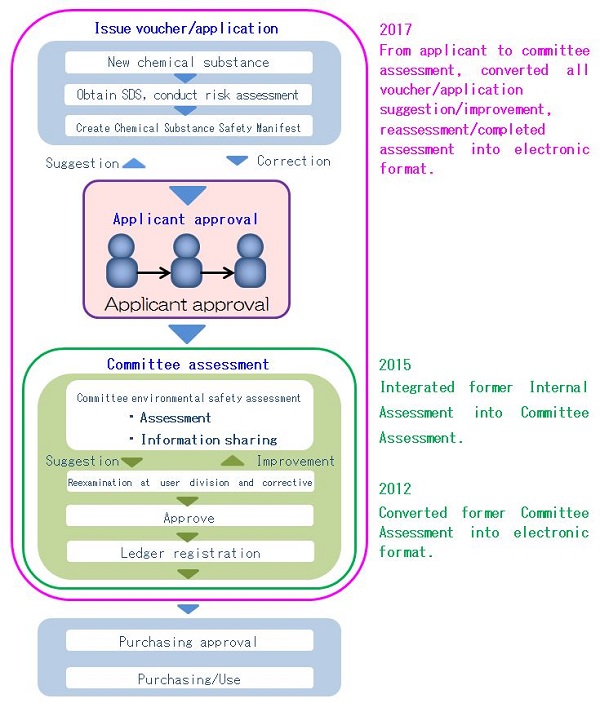

In consideration of workers’ safety and health, and looking to lower environmental impact, we are working to improve the management of chemical substances. We will present examples of our initiatives.Streamlining the system for chemical substance registration

First, we will explain chemical substance registration.

In the environmental safety assessment, our internal preliminary assessment system, we not only assess new chemical substances, but also the installation of production equipment, construction, waste discharge, and non-regular work that is considered a safety problem. Regarding the use of chemical substances, we will create our own “Chemical Substance Safety Form” that contains transportation, storage, handling, disposal and other required information, and conduct assessments.

Procurement only takes place after passing the assessment and registering.

(See the figure below)

New chemical substance preliminary assessment flow based on environmental safety assessment

At JAE, environmental safety assessments including risk assessments were put into electronic format in fiscal 2017, and we began making practical use of them from April 2018.

Through digitization, assessment efficiency was improved, and quick registration of chemical substances is expected in the future.

Reduction of Chemical Substances

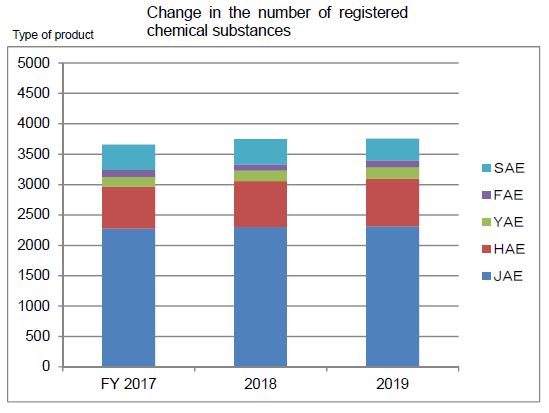

Monitoring Registration of Chemical Substance Product TypesChange in the number of chemical substance product types at production sites in Japan is as visualized in the below graph. The reason that the JAE site has more chemical substances than other production sites is because it is not only involved in production, but is also a development plant and uses chemical substances for testing. The JAE Group monitors whether unnecessary chemical substances have been registered so that the number registered does not increase any further. The Group will move aggressively to reduce the volume of chemical substances used, as shown below.

Reduction of Use of Chemical Substances

In fiscal 2019, we continued as in the previous year to conduct our activities with the goal of reducing the amount of chemical substances used by selecting designated substances for each domestic production base in order to reduce our environmental impact. The main chemical substance reduction activities for fiscal 2019 are listed below, and we will continue to work to reduce chemical substance use.

- JAE:

- Reduced the amount of deposited gold needed for gold plating

Reduced registered substances by rationalizing production, and reduced substitutes and organic solvents

- HAE:

- Reduced chemical substances used during plating treatment

Reduced amount of Isopropyl alcohol by reducing evaporation

Reduced injection chemicals used in plating waste liquid disposal

- YAE:

- Reduced the amount of parts cleaner purchases

- SAE:

- Reduced amount of cleaning agent used including 1-bromopropane

PRTR Data

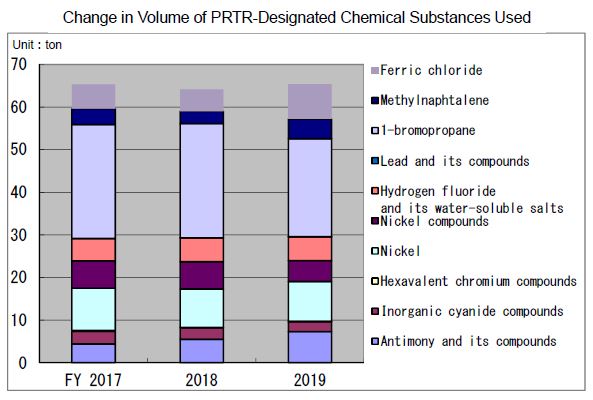

The graph below shows the change in the amount of chemicals subject to the PRTR Law (*use cursor to view definitions) that was used by production sites in Japan.The increase of methylnaphthalene contained in heavy oil was caused by the operation of a reserve chiller that uses heavy oil due to air-cooled chiller malfunction. The increase in ferric chloride used in the flocculating agent for plating impurities was temporarily increased due to the need to adjust the plating solution when upgrading or adding plating equipment.

To deal with PRTR-designated chemical substances, we reduced the amount of 1-bromopropane used as a cleaning agent due to the installation of a regenerator at SAE. We will continue to promote the use of recycled products (recycling) and repeated use (reuse) to reduce the amount of materials we handle.

VOC Information

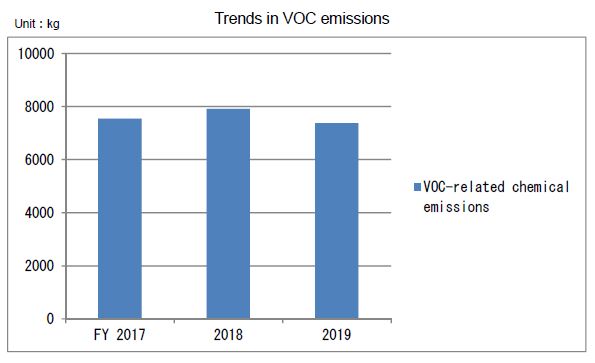

The total volume of chemical emissions of VOCs (use cursor to view definition) and related substances for production sites in Japan is shown in the graph below. VOC emissions increased due to an increase in production using ethanol as a cleaning agent at SAE. To reduce emissions, we will further improve container sealing and re-examine the amount handled.Building a sustainable world

Significance of the 2020 Environmental Report

Symbol of the Group's Environmental Policies

Scope of Reporting and Editorial Policy

Policies and results of environmental activities

Environmental Management

- Implementation Status of the Environmental Management System

- Environmental Audits

- Environmental Education

- Environmental Risk Management

- Environmental Accounting

Engaging with Society

- Involvement with biodiversity

- Supply Chain Management

- Eco-friendly Products

- Social contribution activities

- Environmental Activity History

Initiatives to reduce environmental impact