Environmental Report 2020

Measures against Climate Change

The fight against climate change is a crucial global issue that requires the further involvement of each and every person and organization.

The JAE Group in Japan is working to address climate change through environmental awareness training, production–related measures, and measures at plant facilities.

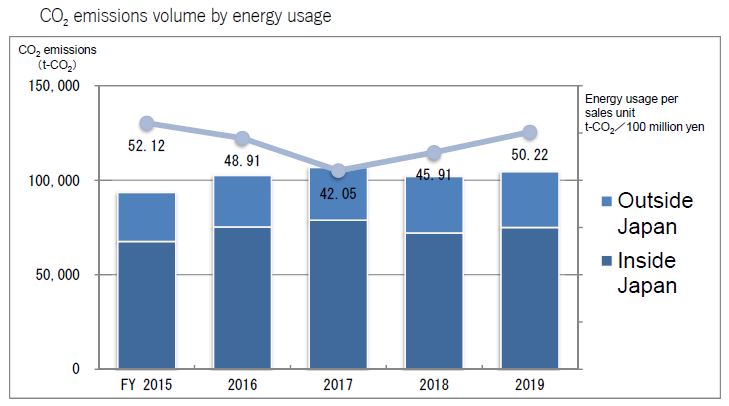

Amount of Carbon dioxide Emitted by the JAE Group in Japan

Total carbon dioxide (CO2) emissions of the JAE Group in Japan in fiscal 2019 were 74,960 tons, an increase from fiscal 2018, and also emissions per unit of sales increased.The main cause was the effect of production volume. We will continue to further promote energy saving in infrastructure and production equipment, and to carry out efficient production while monitoring total CO2 emissions and emissions per unit of sales.

※Energy usage per sales unit is shown as unit of CO2 emissions in Japan and overseas, and consolidated net sales (unit: t-CO2/100 million yen)

※The equivalency factor for CO2 emissions due to energy use is the value published by the Federation of Electric Power Companies. In fiscal 2019, the fiscal 2018 result (0.463 ton-CO2/MWh) is being used.

Status of progress toward uniform goals in the electrical and electronics industries

The JAE Group in Japan participates in the electrical and electronics industries’ Action Plan for Achieving a Low Carbon Society and is progressing toward the goal of a 1% annual average energy efficiency improvement in production processes through 2030.Although total energy usage is increasing in line with higher production volumes, we have curbed energy usage per unit by taking steps to contribute to the fight against climate change.

In fiscal 2019, the improvement rate was 27.57% on a per-unit of energy basis, surpassing the goal of 6.79%.

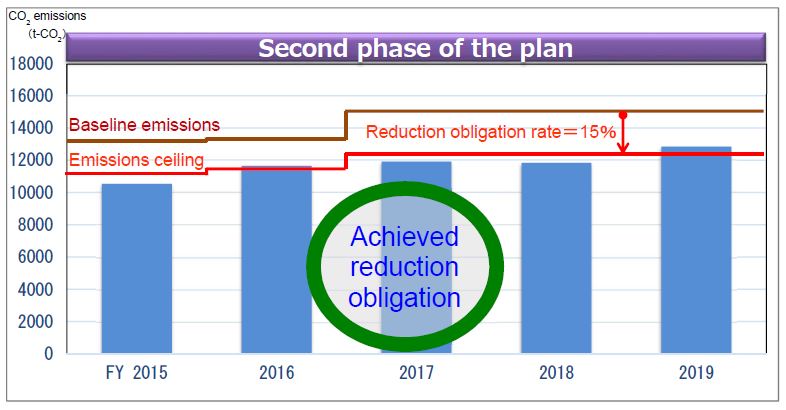

Status of Response to Tokyo Cap-and-Trade Program

The Akishima Plant has an obligation to cut greenhouse gas emissions by an annual average of 15% during the second phase of the plan from fiscal 2015 to fiscal 2019.Emissions in fiscal 2019 were down 13.9% from the baseline emissions and our 15% annual reduction target was not achieved, but a 17.4% reduction was achieved in the second phase of the plan.

The Akishima Plant has an obligation to reduce emissions by 25% in the third phase of the plan from fiscal 2020 to 2024. As it is, achieving the reduction obligation will be difficult, so we will make further efforts to fight global warming by introducing renewable energy and other measures.

Fiscal 2019 Energy Conservation Case Studies

1. Plant facilities

| Implemented content (1) | ||

| Reduction of loss by replacing substation transformer (JAE) | We adopted a highly efficient amorphous transformer. ・Replaced the substation transformers of office buildings. ・Simultaneously integrated transformers (6 units→4 units) and re-examined capacity. ・Replaced 1 substation transformer at No. 2 Plant |

|

|

Result | Status |

| 27,966 kWh/year (office building) 11,009 kWh/year (No. 2 Plant) |

Need to replace substation transformer. (Every 30-35 years) Performed scheduled replacement of high-efficiency equipment from fiscal 2012. (Replaced 8 units up to fiscal 2018) A more efficient amorphous transformer was adopted from 2019. We plan to replace one high-voltage power receiving station, three substations at No. 3 Plant, thirteen substations at No. 1 Plant, and two substations at the gymnasium with high-efficiency transformers by 2025. |

|

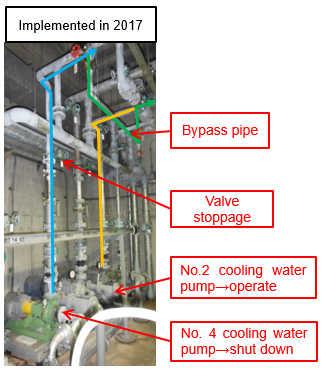

| Implemented content (2) | ||

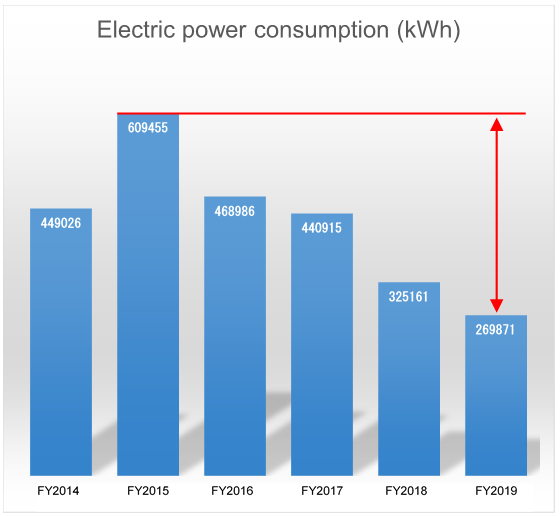

| Integrated cooling water pump for use in production at No. 1 Plant (JAE) | 2In fiscal 2017, we achieved energy saving by installing a bypass pipe for the two cooling water pumps used in production that had operated individually, and integrated them into one unit, and removed the other unit from service. | |

|

Subsequently, pump capacity was inadequate due to an increase in equipment that uses cooling water, so the cooling water pump was replaced in fiscal 2019 with an inverter type cooling water pump unit, loads were integrated, and two units were shut down. Further energy saving was achieved by inhibiting the output so that cooling water pressure is constant according to the load. | |

|

Result | Status |

| 98,988kWh/year (varies with load) *FY2017 results: 94,600kWh/year |

Handle depending on operating status | |

| Implemented content (3) | ||

| Reduced electric power for clean room air conditioning | Optimized the settings of air conditioners (indoor temperature settings were made more efficient, while the difference between sensor dehumidification operation and reheat was reduced) installed in clean rooms (two locations) of the Akishima Plant. | |

|

Result | Status |

| 339,584kWh/year (compared with FY2015 results) |

Other air-conditioning equipment is also available in the plant | |

2. Lighting

| Implemented content (1) | ||

| Switched from mercury lighting to LED lighting (JAE) | Implemented plan to upgrade outdoor lights, high ceiling lights, and floodlights to LED lighting. Upgraded tennis court lighting (12 lights) in fiscal 2019 | |

|

Result | Status |

| 695kWh/year (FY2019) (reduced by 54,574kWh from fiscal 2013 to 2018) |

Systematic implementation from fiscal 2013. 91 lights were replaced in fiscal 2018, and 12 lights were replaced in fiscal 2019, for a total of 103 lights. | |

| Implemented content (2) | ||

| Upgraded to LED lighting (JAE) | ・Replaced 21 ceiling lights in the elevator hall of the No. 1 Plant ・Replaced 276 ceiling lights on the 3rd floor of the No. 1 Plant ・Replaced 65 ceiling lights on 3rd floor of office building ・Replaced 117 ceiling lights in the changing room of the No. 1 Plant ・Replaced 66 ceiling lights in bathrooms of No. 1 Plant |

|

| Result | Status | |

| 43,810kWh/year | LED lighting has been systematically installed in buildings since fiscal 2013. We plan to systematically upgrade lighting in the old office building and on the 1st floor of the No. 1 Plant. | |

3. Production equipment related

| Implemented content (1) | ||

| Attachment of insulation covers to molding machines (HAE) | Attached 61 heat insulation covers to molding machine cylinders. | |

|

Result | Status |

| Total of 511,000kWh/year |

Installed a total of 230 units, planned implementation will continue. | |

| Implemented content (2) | ||

| Reduced by lowering compressor load by checking for air leaks (YAE) | Purchased “Air Detector,” an air leak detecting device, to check equipment connections and improve air leaks. | |

|

Result | Status |

| 962,000kWh/year |

Planned implementation will continue. | |

4. Activities of overseas production bases

| Implemented content (1) | ||

| Reduced electric power consumption (JAE-OR) | Participated in Strategic Energy Management (SEM) program and monitored 30 items capable of energy saving. ・Managed lighting equipment with motion sensors ・Reviewed volume of air compressor setting ・Replaced 12 fluorescent lights with LED lighting |

|

| Results | Status | |

| 72,865 kWh/year | The remaining items will be implemented | |

| Implemented content (2) | ||

Plant energy-saving activities (JAE-WJ)  |

Strengthened electric power management. ・Monitored, analyzed, and studied daily electricity usage. ・Checked production status and efficiently started up compressor/nitrogen equipment. ・Managed air conditioner temperature/humidity settings ・Improved facility/equipment maintenance and operating rate ・ Conducted energy conservation training for employees twice a year. ・Stopped using old air conditioners and replaced them |

|

| Results | Status | |

| 666,632kWh/year |

Not calculated | |

| Implemented content (3) | ||

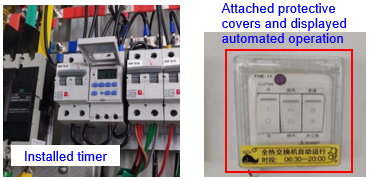

Streamlined the use of all plant air conditioners and ventilation equipment total heat exchangers (JAE-WX)  |

Managed air conditioner use ・Managed temperature settings, 26°C or higher in summer, 18°C or lower in winter. ・Attached protective covers to prevent adjusting of temperature. ・Clarified management of public area managers ・Managed use of total heat exchanger: Installed timer on switchboard |

|

| Results | Status | |

| Not calculated | Not calculated | |

5. Logistics related

Reduced CO2 through improved efficiency by examining the operating routes of cars and reducing the number of vehiclesReduced CO2 by discussing with the customer whether efficiency of the regular service can be improved, examining the routes of operation, and reducing the number of vehicles.

Results of fiscal 2019;

Reduction of 35.92 ton-CO2.

Activities to Increase Awareness of Measures to Fight Climate Change

Introduced here are several fiscal 2019 efforts made to increase awareness of climate change measures.- No Driving Day

- Eco-driving training

- Clean up campaign around each work site, and other activities

(For details, see the Environmental Education section[click to open])

- Cool Biz (May 7 through October 31)

- Warm Biz (November 1 through March 31)

July 7: “Tanabata Lights Down” (Cool Earth Day)

Measures to fight climate change through supply chain cooperation

The JAE Group asks its domestic suppliers to agree to and implement greenhouse gas emission reductions in line with its CSR guidelines, and it aggregates the annual of energy purchases of each company. The top 20 companies that the Group transacts business with (excluding trading companies) have slightly decreased the amount of power they purchased since fiscal 2018.Building a sustainable world

Significance of the 2020 Environmental Report

Symbol of the Group's Environmental Policies

Scope of Reporting and Editorial Policy

Policies and results of environmental activities

Environmental Management

- Implementation Status of the Environmental Management System

- Environmental Audits

- Environmental Education

- Environmental Risk Management

- Environmental Accounting

Engaging with Society

- Involvement with biodiversity

- Supply Chain Management

- Eco-friendly Products

- Social contribution activities

- Environmental Activity History

Initiatives to reduce environmental impact