Environmental Report 2020

- Return

- 20 / 20

Zero Emissions

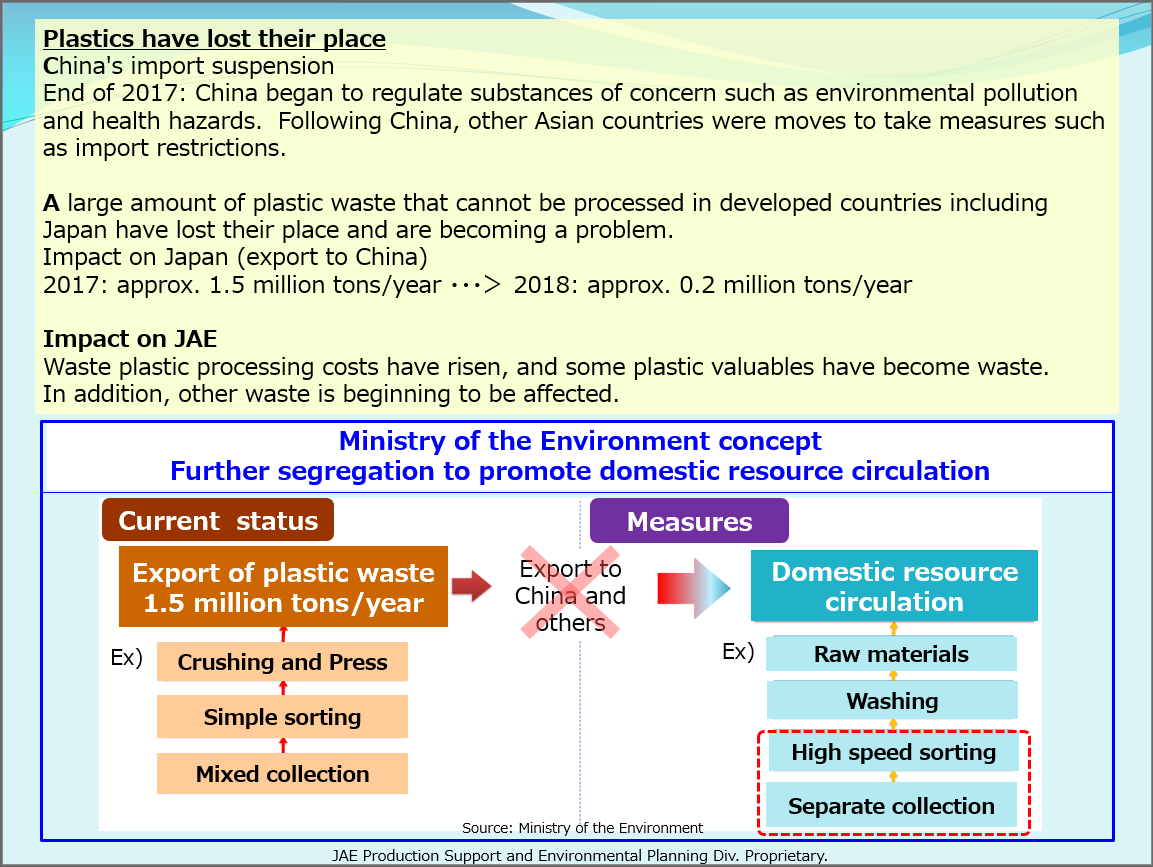

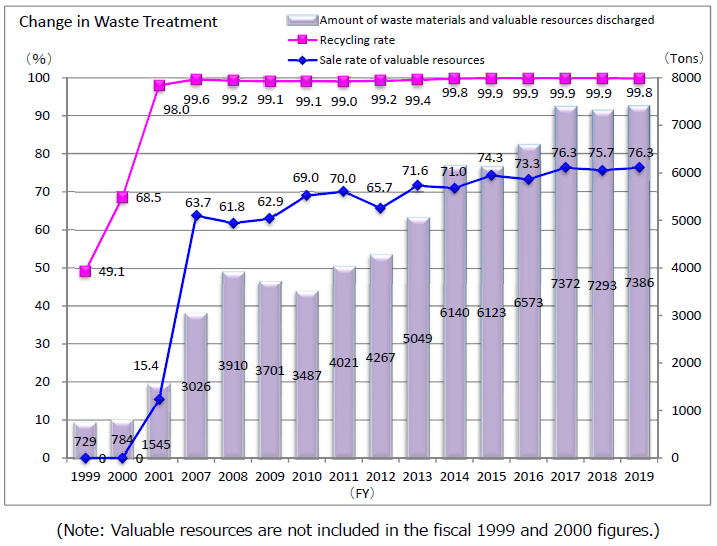

The JAE Group makes effective use of resources by reducing general waste and consuming less paper, while promoting recycling and the sale of valuable resources through the exhaustive sorting of waste, such as scrap plastic and metal.

Zero Emissions Activities

JAE achieved a recycling rate of 99% in fiscal 2004, and since then we were able to reach a high point of 99.8% in fiscal 2014 by taking continuous action. As a result, the target was raised to over 99.5% in fiscal 2015, and to over 99.8% in fiscal 2019.

We sought to sell valuable waste such as plastic and metal waste and worked to reduce costs for waste treatment. The sale of valuable waste contributes to resource saving and the reduction of CO2 over the life cycle of products. The Group aims to achieve even higher rates of sales.

Note: The JAE Group defines zero emissions as achieving a recycling rate of 99.5% or higher for waste defined by local ordinances, excluding waste that is disposed of by incineration and simple landfills.

Efforts for Proper Disposal of Waste Materials

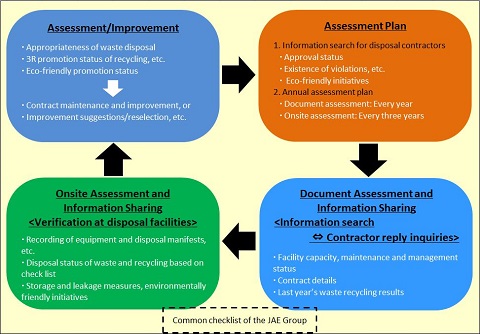

The JAE Group is implementing proper disposal of waste materials in accordance with Japan's Waste Management Law. The Group verifies the appropriateness of subcontractors that handle all types of industrial waste, general waste, and valuable resources at the time of contract signing and thereafter by periodically checking their licenses and performing on-site inspections.In fiscal 2017, we created a check list to clarify items to be checked and points to be changed for disposal contractors and to enhance communication with them.

Main Activities in Fiscal 2019

The main efforts to reduce wastes are shown below.We are pursuing value-added recycling, such as removing metal from complex waste, by prioritizing efforts on waste that is discharged in large quantities due to increased mass production.

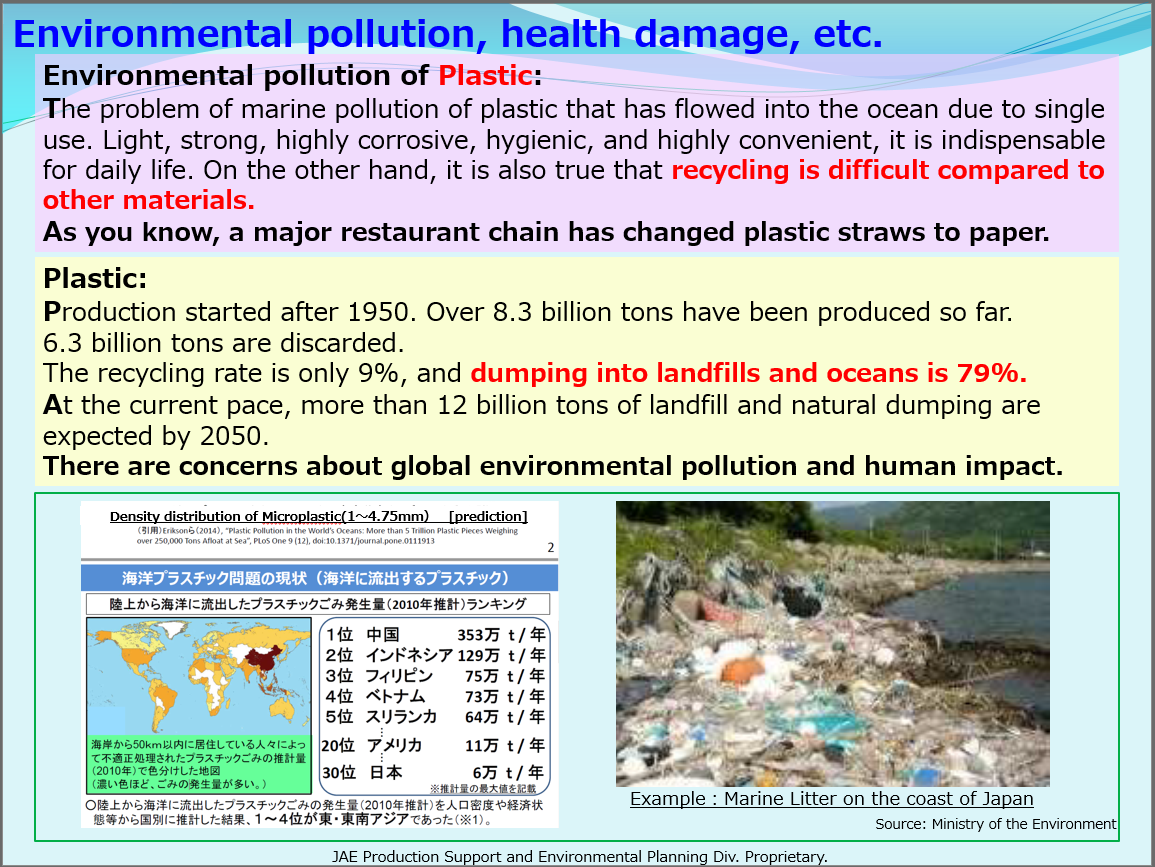

In waste education, we teach that environmental pollution is caused by waste and we include information that can be put into daily practice.

The company will continue its efforts toward eradicating defects and promoting manufacturing that is environmentally friendly.

- Return

- 20 / 20

Building a sustainable world

Significance of the 2020 Environmental Report

Symbol of the Group's Environmental Policies

Scope of Reporting and Editorial Policy

Policies and results of environmental activities

Environmental Management

- Implementation Status of the Environmental Management System

- Environmental Audits

- Environmental Education

- Environmental Risk Management

- Environmental Accounting

Engaging with Society

- Involvement with biodiversity

- Supply Chain Management

- Eco-friendly Products

- Social contribution activities

- Environmental Activity History

Initiatives to reduce environmental impact