Environmental Report 2013

Measures against Climate Change

The fight against climate change is a crucial global issue that requires the further involvement of each and every person and organization. The JAE Group is working to address climate change through the teaching of environmental awareness, production-related measures, and measures at plant facilities, and it has set definite objectives and targets for its environmental activities. Since FY 2010, the group has been promoting energy saving among employees through an e-learning program.Status of Response to Common Target of Electrical/Electronics Industries

Total CO2 emissions from the domestic JAE Group in FY 2012 were 49,097 tons, an approximately 20% increase over the previous fiscal year. The main cause of this increase was the abrupt worsening of the equivalency factor for CO2 emissions from electric power starting in FY 2011.Beginning in FY 2013, the domestic JAE Group will be participating in the industry's action plan for a low-carbon society, with a target of a 1% annual average improvement in energy intensity up to 2020.

CO2 emissions due to energy use per unit of real sales

Change in domestic JAE Group average emissions per unit of real sales

*Average CO2 emissions per unit of real sales = CO2 emissions divided by real sales.

Real sales is an indicator adjusted for the steep drop in prices in the electrical/electronics industry, and is obtained by dividing sales by the Bank of Japan's domestic corporate goods price index (in the field of electrical equipment).

Real sales = sales divided by the domestic corporate goods price index (electrical equipment)

*The equivalency factor for CO2 emissions due to energy use is the value published by the Federation of Electric Power Companies. In FY 2012, the FY 2011 result (0.476tons-CO2/MWh) is being used.

Status of Response to Tokyo Cap-and-Trade Program

The Akishima Plant has an obligation to cut greenhouse gas emissions by an average of 6% during the first phase of the plan from FY 2010 to FY 2014.FY 2012 emissions were down about 30% from the standard emission value, enabling a reduction exceeding the initial plan. During the first phase of the plan, JAE expects to achieve its reduction obligations through its own efforts toward maintaining its current measures.

The company's application for changing the standard emission value in accordance with changes in its construction compared to standard years, including the building of a Welfare Office Building and No. 5 Plant, was withdrawn because it did not satisfy the requirements for change applications in accordance with the Tokyo metropolitan government's decision on the method for estimating the amount of increase/decrease.

FY 2012 Energy-Saving Measures

[Examples of production-related energy-saving measures]

●Saved energy by increasing the production efficiency of pressing and plating processes.

●Replaced CNC lathes and thermo/humidistat baths with more energy-efficient models.

●Saved energy by inspecting air guns and pipes for air leaks and repairing those that are found.

●Saved energy by stopping clean room ventilation at night and on days off.

●Saved energy by increasing use of vacuum pump equipment.

The amount of electric power used was cut by increasing the number of units in operation and their operating time for equipment that was modified from factory air to vacuum pumps.

[Examples of energy savings at plant facilities]

●Replaced 230 lighting fixtures with energy-saving lighting equipment (AlLine).

●Installed inverters on water cooling pumps and switching to Eco-Pumps.

●Reduced power consumption by switching computer room air conditioning from a centralized system to individualized systems (all-in-one air-conditioning systems).

Climate change awareness activities

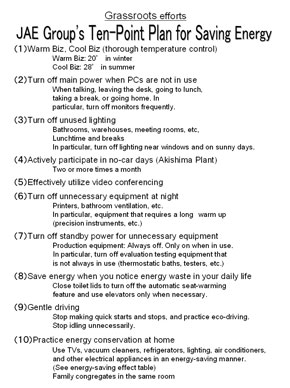

Climate change awareness activities have been underway as grassroots efforts since FY 2010. These grassroots efforts have been based on the Ten-Point Plan for Saving Energy and the Environment Month, and in FY2012, the following activities were undertaken.- Environment Month (June 1 to June 29)

- Environmental education concerning energy saving (For more information, see the “Environmental Education“ page.)

Some 3,000 domestic employees learned about the environment through e-learning. - Warm Biz and Cool Biz

Cool Biz (May 7 through October 31)

Warm Biz (November 1 through March 31) - Participation in energy-saving “Lights Down“ campaign (June 21 and July 7)

Lights were turned down on building billboards and elsewhere (day and night). - No driving day

The company implemented a no driving day twice a month throughout the year with the aim of reducing CO2 emissions. As part of the activity, employees who commute by car are surveyed every month about compliance, which also serves to raise awareness. - Eco-drive workshop (February 27)

An outside instructor was invited to hold a short training course. - Awareness survey on employee energy-saving activities in their homes (June)

It was discovered that many employees where taking the energy-saving measures implemented within the company and applying them at home.

Posters for Cool Biz and Warm Biz implemented at domestic Group companies

Ten-Point Plan for Saving Energy implemented by Group companies in Japan along with all their employees