Environmental Report 2024

Measures against Climate Change

The fight against climate change is a crucial global issue that requires the further involvement of each and every person and organization.

The JAE Group in Japan is working to address climate change through environmental awareness training, production–related measures, and measures at plant facilities.

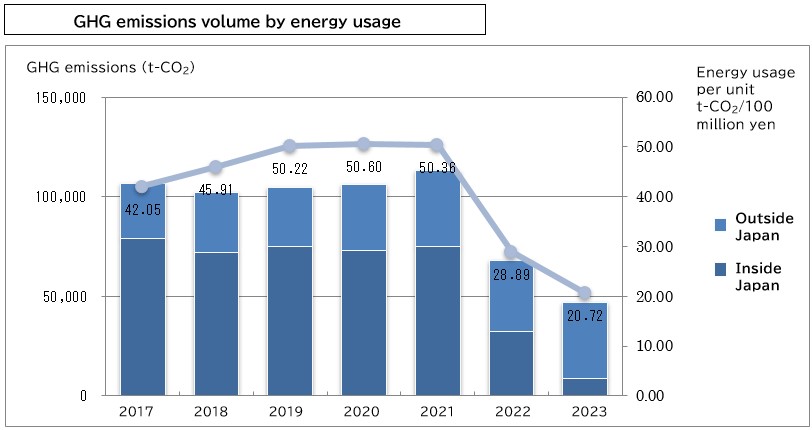

Amount of GHG Emitted by the JAE Group

Total greenhouse gas (GHG) emissions by the JAE Group in fiscal 2023 were 46,772 t-CO2 (a 31.4% reduction from 2022), and CO2 emissions per sales unit also decreased significantly compared to the previous fiscal year.This reduction was attributed to the introduction of electricity from renewable energy sources at SAE, FAE, MGC, and JAE (including NLC) starting in autumn 2023, in addition to the introduction of HAE and YAE in fiscal 2022, and the promotion of energy-saving initiatives across the entire Group.

*Energy usage per sales unit (*use the cursor to view definition) is shown as unit of CO2 emissions in Japan and overseas, and consolidated net sales (unit: t-CO2/100 million yen)

* The equivalency factor for CO2 emissions due to domestic energy use is based on the value published by each electric power company in the Ministry of the Environment’s list of calculation methods and emission factors.

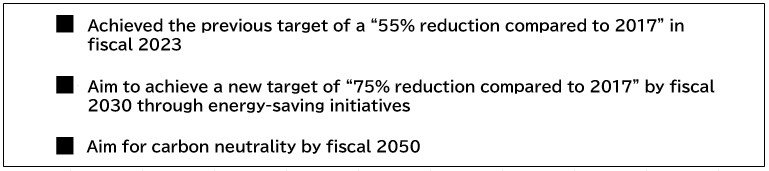

We set a greenhouse gas reduction target of 55% by 2030 (compared to 2017). However, thanks to our initiatives, we achieved this target early, with a 56.2% reduction in actual greenhouse gas emissions (compared to 2017) in fiscal 2023. Therefore, we have established the following new targets (covering Scope 1 and 2 emissions at domestic and overseas production sites). Moving forward, we will continue our efforts to achieve carbon neutrality by 2050.

As a Groupwide activity that includes overseas production sites, we will continue to monitor our electricity consumption, greenhouse gas emissions, and emissions per sales unit, while further promoting energy savings in infrastructure and production equipment, efficient production, and the introduction of renewable energy. Starting in fiscal 2022, we have doubled the previous energy-saving targets and implemented energy-saving measures at each production site, as illustrated in the examples below. Last year, we also received an energy-saving diagnosis from external experts, and we will continue promoting energy conservation.

Regarding the introduction of renewable energy, in addition to HAE and YAE that introduced it in fiscal 2022, we switched to 100% renewable energy-derived electricity at four domestic production sites and NLC, and installed solar power generation equipment, as outlined below, on the rooftop of the JAE Akishima Plant. The results of this system's operation will be used to determine its implementation at other sites.

Status of response to SBT

The JAE Group had received てSBTi 1.5°C certification as part of the NEC Group. However, as of March 22, 2024, the JAE Group changed its status from a consolidated subsidiary of NEC Corporation to an equity method affiliate, and will actively pursue obtaining SBT certification as the JAE Group.Status of progress toward uniform goals in the electrical and electronics industries

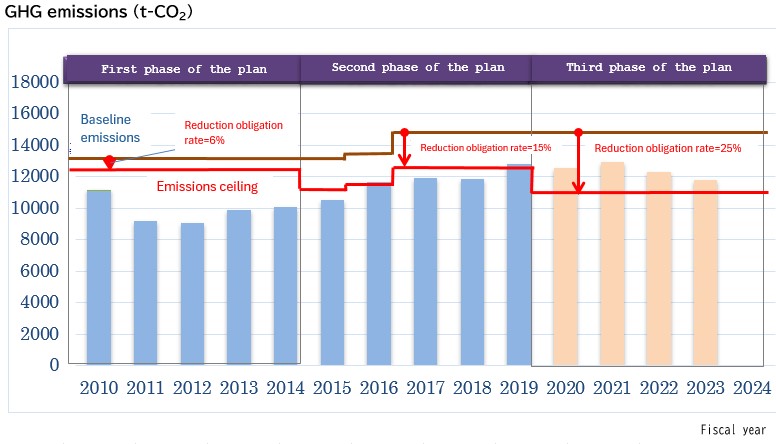

The JAE Group in Japan participates in the electrical and electronics industries’ Action Plan for Carbon Neutrality and is progressing toward the goal of a 1% annual average energy efficiency improvement in production processes through 2030.We will continue to curb energy usage per unit by taking steps to contribute to energy savings.

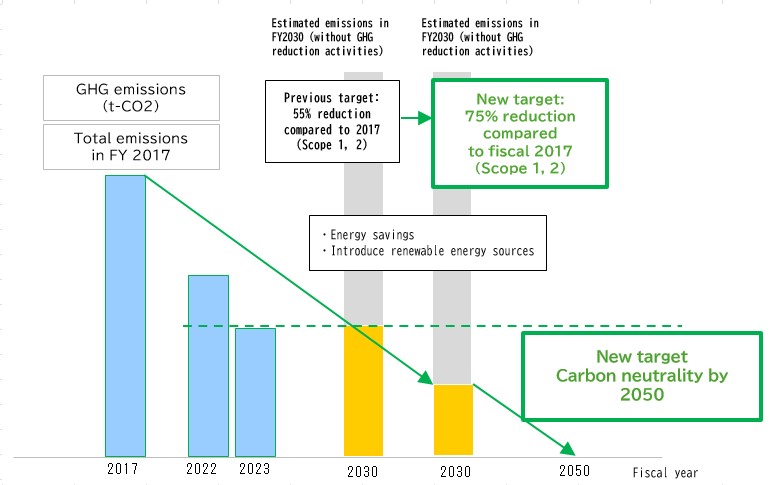

Status of Response to Tokyo Cap-and-Trade Program

During the second compliance period from fiscal 2020 to fiscal 2024, companies must reduce CO2 emissions by an average of 25%, but due to the launch of new products, we did not meet the 25% reduction target from standard emissions in fiscal 2023 for a single fiscal year. At this rate, achieving the required reductions will be difficult, and so we will go even further in pursuing measures to address climate change, including introducing renewable energy.

Contribution of the JAE Group Forest

The Group has estimated that the amount of greenhouse gases (CO2) absorbed through the planting of Japanese cypress and broadleaf trees in the JAE Group Forest is about 5.3 tons-CO2 per year.Fiscal 2023 Energy Conservation Case Studies

Plants and related facilities and production system

| Implementation details (1) | ||

| Reduction of power consumption by turning off the power at production facilities (print curing furnaces) when not in operation (UIS) |

The print curing furnaces used in production were operated with the power always on to ensure stable quality. However, by conducting stability evaluation checks focusing on processes with low impact, we were able to turn off the power during non-operating hours. By gradually applying this method, we aimed to reduce energy consumption. | |

| Effect | Notes | |

| Approx. 739,568 kWh/year |

― |

|

| Implementation details (2) | ||

| Conserving power by controlling the number of air compressors operating (HAE) | Air used in the factory is generated by multiple compressors, stored in air tanks, and delivered throughout the facility. However, there were instances of excess air generation due to manual monitoring and switching on and off of the air tank pressure. By installing a unit that controls the number of compressors and automatically turns them on and off, we eliminated excess air generation. Additionally, compressors that are on can now operate at full capacity (the most efficient state) at all times. | |

|

Effect | Notes |

| 1,599,566k Wh /year |

― | |

| Implementation details (3) | ||

| Power reduction through installation of high-efficiency transformers (YAE) | Following the expansion of Building B of Factory No. 2, we installed high-efficiency transformers (amorphous transformers) to significantly reduce no-load losses. As a result, we achieved a reduction of 177,828 kWh per year. | |

| Effect | Notes | |

| 177,828kWh /year |

― | |

JAE lighting

| Implementation details (1) | ||

| Switched to LED lighting (JAE) |

|

|

|

Effect | Notes |

| Total of 55,477kWh /year |

Lights in buildings have been systematically changed to LED lighting since fiscal 2013. We plan to systematically update lighting in the welfare office building and Factory No. 1 floors that has become outdated. As of the end of fiscal 2023 7,690 LED lights out of 11,041 lights Progress rate: 70% |

|

Activities of overseas production bases

| Implementation details (1) | ||

| Factory energy-saving activities (JAE-WJ) Lighting control with infrared motion sensors  |

Electricity savings improvement was achieved by implementing lighting control with infrared motion sensors, resulting in a reduction of 11,892 kWh/year. | |

| Effect | Notes | |

|

Total 11,892kWh /year

|

ー | |

Logistics related

1) GHG reductions from modal shift (railway transport)

Reduced CO2 emissions by switching from truck transport (crates) to railway transport (containers)

Fiscal 2023 GHG emissions were reduced by 3.3 t-CO2 (compared to truck transport)

2) GHG emissions reductions by using reusable trays

GHG emissions were reduced by reusing trays for connectors.

Fiscal 2023 GHG emissions reductions = 117.5 t-CO2 reduction

*45.9 tons of reusable trays/year x conversion factor of 2.56 t-CO2 = 117.5 t-CO2

Activities to Increase Awareness of Measures to Fight Climate Change

Introduced here are several fiscal 2023 efforts made to increase awareness of climate change measures.Environment Month publicity and a wide range of Environment Month activities were held at each site.

- Eco-driving training

- Clean-up campaign around each work site, and other activities

All employees of the JAE Group in Japan took part in e-learning.

(For details, see the Environmental Education section(click to open))

● Cool Biz and Warm Biz: Domestic JAE Group

- Cool Biz (May 1 through October 31 [e.g., period at JAE])

- Warm Biz (December 1 through March 31 [e.g., period at JAE])

Measures to Fight Climate Change through Supply Chain Cooperation

The JAE Group asks its domestic business partners to agree to and implement greenhouse gas emission reductions in line with its CSR guidelines, and it is taking measures to fight global warming throughout the supply chain.Building a Sustainable World

Significance of the 2024 Environmental Report

Symbol of the Group's Environmental Policies

Scope of Reporting and Editorial Policy

Policies and Results of Environmental Activities

Environmental Management

- Implementation Status of the Environmental Management System

- Environmental Audits

- Environmental Education

- Environmental Risk Management

- Environmental Accounting

Engaging with Society

- Involvement with Biodiversity

- Supply Chain Management

- Eco-friendly Products

- Social Contribution Activities

Initiatives to Reduce Environmental Impact